The emergence of Cobots in recent years has magnified the amount of labor a single human can do. There is great potential in its capacity to enhance an organization’s human staff, enhancing the manufacturer’s productivity and output quality.

And because they are programmed and automated, cobots can perform manual, repetitive tasks with consistent outcomes. This enables skilled operators to focus on more complex tasks. In turn, the firm’s production speed and efficiency improve.

In this article, we answered people’s most commonly asked questions about cobots to shed light on the impressive capabilities of this modern manufacturing solution.

The Most Common Questions about COBOT

In this section, we fired up questions typically asked by both casual and professional welders about cobots.

1 - What Types of Welding Can Cobots Perform?

From old-school welding techniques (e.g., MIG and TIG) to modern solutions, there are cobots specifically designed to perform certain welding methods.

For instance, a MIG-based cobot manipulates a metal inert gas (MIG) torch with controlled speed and consistent angles. The wire feeds automatically through the gun as the arm traces each joint. The cobot maintains a steady torch distance and travel speed, which ensures even bead profiles and strong fusion.

There are also laser-welding cobots that use a focused laser beam to fuse metals with pinpoint accuracy. Here, the cobot follows a programmed seam as it guides the laser head along. A laser welding cobot often produces small heat-affected zones (HAZ) and cleaner edges, which is highly important when working with thin and delicate metals.

Other types of welding that cobots can support include tungsten inert gas (TIG) welding, flux-cored arc welding (FCAW), stud welding, hot wire welding, and more.

2 - How Are Cobots Different from Traditional Robots in Welding?

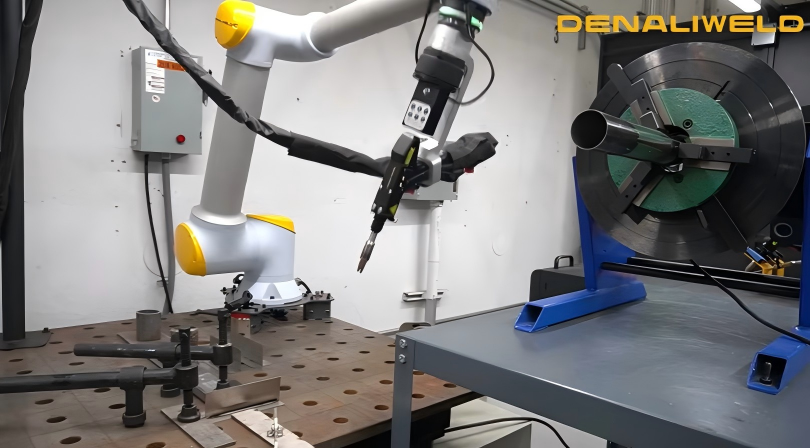

Cobots are designed to work right next to human personnel. You do not put these machines inside fenced-off zones since they are engineered with utmost safety in mind. An operator and a cobot can perform their respective tasks without the cobot harming the staff.

For instance, the human operator can load a steel workpiece into a custom fixture on a welding table. The cobot, which is already programmed for a specific fillet weld, waits nearby. Once the workpiece is clamped, the operator presses a start button on the cobot’s interface. The cobot moves in, aligns its torch to the joint, and starts welding according to the programmed path.

Now, when the cobot completes its automated weld seam, the operator inspects the previous part just finished. If the operator spots a tack weld or any bracket that requires manual touch-up (usually due to a tight corner or a spot inaccessible for the cobot’s arm), the operator will quickly fix it using a handheld torch.

On the other hand, traditional welding robots require safety cages because they move with greater speed and force compared to cobots. Furthermore, they lack “awareness” of their surroundings because they do not have sensors that detect humans or obstacles in real-time. So, if a staff member steps into their path, the robot will not stop, which can cause serious physical injury.

3 - Can Cobots Work Safely Alongside Humans?

Most cobots are built and programmed to operate beside people without putting anyone at risk. They come with real-time sensors that can detect any nearby worker or object. Upon detection of an obstacle or a person, the cobot will immediately adjust its speed and force. And if the person becomes extremely close to any of the cobot’s components, the machine automatically stops. It will only reactivate once the worker is sufficiently far from the cobot.

If your project involves several repetitive tasks that strain the body, cobots may take over them with ease. They can handle menial tasks such as lifting, precision assembly, and long periods of tool positioning. These jobs usually cause fatigue, joint pain, or long-term ergonomic injury when done by humans alone. By sharing the workload, cobots help create safer and more sustainable production floors.

4 - How Does Programming and Operation Work for Cobot Welding Cells?

Most cobot welding cells require low or zero-code programming environments. This means that operators may work alongside cobots even with minimal know-how of the robotic systems. This is because most systems come with intuitive features like guided teaching tools, touchscreen menus, and drag-and-drop command blocks.

In fact, some cobots can “imitate” what a human welder does. An operator moves the torch by hand, sets the weld path, and “saves” the sequence. The cobot then records each point with precision and repeats the motion with consistent quality.

5 - What is the Typical Cost and ROI of Implementing Cobot Welding?

Depending on the cobot model and features, a unit costs around USD80,000 to USD150,000. Meanwhile, since cobots are known for their pinpoint accuracy, unparalleled speed, and 24/7 availability, a cobot welder’s ROI is faster and better than traditional welding robots.

To calculate ROI, we use this mathematical formula:

ROI = (Net Profit From the Investment / Cost of the Investment) x 100%

It depends on the firm’s productivity how much ROI it will gain from cobots. But on average, a firm may expect ROI from a cobot welder in as few as 18 to 24 months.

6 - Can Cobots Handle Large or Complex Parts?

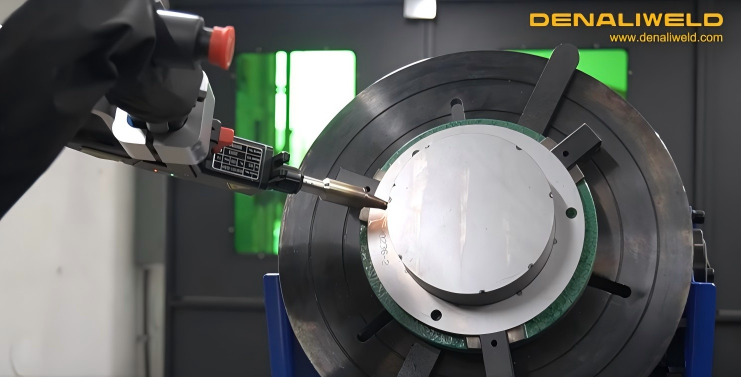

Cobots can manage large or complex parts as long as they have the right tools and modular add-ons. Many cobot systems have external axes, rails, or arm extensions that expand the cobot’s reach far beyond its base envelope. These upgrades allow the robot to travel along long weld seams, cover wide assemblies, or reach deep corners that a standard setup cannot access.

7 - What Are the Key Benefits of Cobot Welding?

Cobot welding ensures better weld quality and consistency as it follows programmed paths with precise torch angles and speeds. Moreover, cobots can take over repetitive welding tasks, which can minimize muscle strain, awkward postures, and exposure to heat and fumes for the human welder. This results in fewer injuries and a safer work environment.

8 - Challenges and Limitations of Cobot Welding

As with other welding solutions, cobot welding also comes with several downsides and limitations. For instance, cobot welders have limited payload capacity and welding speed when stacked against larger industrial robots. These machines are best suited for lighter loads, as they often struggle lifting the heavier ones.

Moreover, cobots require regular maintenance to operate efficiently. You must inspect the machine for any signs of wear and tear, as well as calibrate its settings periodically to ensure that its parameters are still aligned to the project at hand.

9 - How to Get Started with Cobot Welding?

Prior to cobot acquisition, assess your current workflow and identify spots where cobots can add value. Determine specific repetitive tasks that may benefit from cobot automation.

Then, choose a cobot that comes with customizable features and modular solutions. This enables you to integrate the cobot in a wide range of industrial applications. Meanwhile, the presence of modular features enables easy upgrades and modifications to your unit without any disruptive downtime or additional costs.

Step Up Productivity and Efficiency With Advanced Cobot Solutions

Cobots are the future of modern manufacturing. They can enhance human productivity and elevate a firm’s production speed and capability. And with their ultra-precision and consistent performance, cobots can level up your output quality at minimal cost. These machines are also safe to use as they feature safety sensors, emergency buttons, and force limitations.

For cutting-edge cobot welding machines, visit Denaliweld. We are a global brand with multiple innovative patents for our superior laser welders. All of our laser welding solutions, including our collaborative robots series, are CE/SGS/WPQR-certified.