DENALIWELD

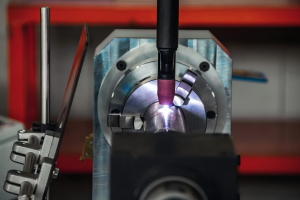

Laser Welding Machine

by Welders & for Welders

JET SERIES

Boost laser welding efficiency with air-cooled portability. Patented CUAL mosaic laser tech, automation-ready design, and pre-set parameters slash downtime—ideal for versatile metals. Minimal maintenance, max ROI.

JET EZ

Ultra-portable laser welding machine (48.5 lbs) with dual welding/seam cleaning. Patented CUAL laser ensures precision on thin metals. Pre-set modes + automation ready—slash setup time & cut operational costs.

JET MOPA

Engineered for precision and power, Denaliweld delivers up to 300W of reliable laser rust cleaning machine and laser welder with one-click operation, compact design, and multi-material compatibility—fast, safe, and efficient.

COBOT Welding

Denaliweld COBOT Welding System delivers precision, flexibility, and seamless automation, proudly self-deployed we offer unmatched COBOT compatibility, one-click operation, and quick setup for modern, efficient manufacturing.

About DENALIWELD.

We Specialize in Laser Welding & Cleaning

DenaliWeld INC, is a proud employee-owned fiber laser welding machine manufacturer based in Chicago, USA. Bolstered by the most experienced engineers and design personnel in the laser industry with multiple innovative patents for our superior laser welders, all DenaliWeld machines are designed and manufactured in Chicago factory and are CE/SGS/WPQR-certified.

Global Services

DENALIWELD, with four branches and more than 150+ dealer stores around the world, dedicates in supplying laser welders & laser cleaners. Our global branches, owning warehouses, are capable in supplying inventory machines, spare parts, 24/7 services, training and showrooms in local and neighboring countries.

Why Choose Us.

DenaliWeld Advantage

Our Services.

We Provide Best Services

Laser Equipment Manufacturer

DenaliWeld, a globally recognized laser welding machine & laser rust removal machine manufacturer, harnesses cutting-edge proprietary technology to dominate the industry, consistently delivering unmatched precision and groundbreaking innovation to our worldwide client.

Local Services

Based in Illinois with 4 global offices, our local teams ensure fast response and professional 24/7 service after your purchase with fair laser welder cost.

Certification

DenaliWeld laser welding machine has passed SGS, CE (MD, EMC), WPQR certification, and C-Test, ensuring world-class quality, compliance with international safety standards, and proven reliability for industrial applications.

Research and Development

With our exceptional R&D capabilities, we stand among the few companies designing and manufacturing in-house laser sources, control systems, coolers, and setups, delivering precision, reliability, & tailored laser weld solutions for various industries.

Explore more about DenaliWeld laser welding solution

Some Partners

Cooperative Partner

We're Ready Anytime.

We Are Available For 24/7 Emergency Services

APPLICATIONS

METAL JOB SHOP

METAL JOB SHOP

Laser welder offers unmatched versatility for diverse materials and thicknesses with minimal heat distortion, slashing production time and costs. It adapts swiftly to various projects, making it a cornerstone of metal fabrication and boosting efficiency with fiber laser welder.

MoreAUTOMOTIVE

AUTOMOTIVE

Laser welder machines are essential for welding body panels, doors, frames, exhaust systems, and fuel tanks. DenaliWeld laser welding machine ensures precise laser welds in complex designs, enhancing safety and fuel efficiency. High-speed automation from laser fiber welding meets massive production demands, solidifying its irreplaceable role in driving automotive innovation.

MoreBOATBUILDING

BOATBUILDING

Boat relies on strong, corrosion-resistant joints in harsh marine conditions. A laser welding machine excels at welding thin materials with precision, reducing weight while maintaining integrity. The laser welding process minimizes heat damage, ensuring durability and making laser fiber welders a must-have for superior vessel construction.

MoreAEROSPACE

AEROSPACE

Aerospace demands perfection, and laser welding machines deliver. They produce clean, high-strength laser welds in exotic alloys and thin materials critical for aircraft components such as engine blades, turbine discs, cabin walls, and doors. The non-contact laser fiber weld process reduces contamination, meeting strict standards.

MoreMOLDS

MOLDS

For mold making, laser weld is key to efficient repairs and modifications. A laser welding machine provides pinpoint laser welds, preserving intricate details with minimal downtime. This precision cuts post-processing needs, saving time and costs with no compromise in molds staying in top shape.

MoreMEDICAL DEVICE

MEDICAL DEVICE

Laser welding machines shine by creating sterile, precise laser welds in biocompatible materials. The laser welding machine ensures consistent quality for tiny components, meeting rigorous regulations. Non-contact laser fiber welding minimizes contamination, enhancing patient safety and making it a critical tool in this industry.

MoreElectronics & Communication

Electronics & Communication

The electronics industry depends on laser welders for delicate, high-speed laser welds without thermal damage. A welding machine supports miniaturization trends, joining small parts with precision for delicate components like circuit boards, chips, sensors, and displays. The repeatability of DenaliWeld welders ensures quality in mass production, cementing their importance in advancing communication technology.

MoreAUTOMATED WELDING

AUTOMATED WELDING

Laser welder machines lead the charge in automated welding, integrating seamlessly with robotics. They deliver consistent, high-quality welds at rapid speeds, cutting labor costs and boosting output. The precision of laser fiber welding makes it ideal for automated lines, revolutionizing productivity across industries.

MoreLatest News.

News & Article

How Manufacturing Cobots Enhance Welding Safety and Productivity

In this article, we highlight the capabilities of a manufacturing cobot in enhancing production efficiency, safety, and productivity. Get to know how to leverage this tech today.

9 Questions about Cobots in Manufacturing, Answered

Cobots in manufacturing can improve firms’ production quality and speed. But many are still clueless about them. In this blog, we answer common questions about cobots.

Troubleshooting Cobot Systems: What to Do in Case of Issues

Learn how to troubleshoot cobot systems effectively, with practical steps, tips for common issues, and guidance to keep your automation running smoothly.

Understanding Precision Cobotics in Welding: How Precise is it Actually?

Learn how precision cobotics improves welding accuracy and consistency, offering a clear view of its real performance, capabilities, and reliability in modern welding.

8 Considerations in Choosing a Cobot Company and Supplier

Discover 8 key considerations in choosing a cobot company and supplier, including safety, support, reliability, integration, training, and scalability.

The Next Step: How Cobot Automation Can Revolutionize Your Operations

Discover in this article how cobot automation for welding can enhance your output quality, workplace safety, and production speed. Learn also how it promotes cost-saving in the long-run.

Our Competences

Are Confirmed By Our Customers

We’re excited to team up with @WeldingTipsAndTricks to push the limits of the DenaliWeld laser welding machine!

It’s not just about speed—it’s also about precision and quality. Want to see the results?

“The laser welder works perfectly! The welds are smooth, strong, and clean. It has significantly improved our production efficiency. Highly recommended!”

“Excellent machine! Easy to operate, very stable, and produces professional-quality results. Our team loves using it every day.”

“This laser welder exceeded our expectations. The precision is outstanding, and it’s perfect for both stainless steel and aluminum projects.”

“After switching to this laser welding machine, our productivity increased by almost 40%. The finish quality is amazing, and no post-polishing is needed.”

“Great investment! Compact design, low maintenance, and very efficient. We use it for custom metal fabrication and couldn’t be happier.”

“Excellent customer service and quick training support. The welder is powerful, reliable, and super easy to learn for new operators.”

“We’ve used many welders before, but this one stands out for its quality and consistency. It delivers clean joints with almost zero distortion.”

CONTACT US

INTERESTED IN DISCUSSING?

Customize a solution to your needs today Experience a live demo and get free samples