It was the Bronze Age, and our ancestors began fusing metals like bronze and copper through heating and hammering. 3,500 years later, medieval blacksmiths innovated forge welding, bonding metals with furnace heat. Over a millennium later, Auguste de Meritens introduced the current-day arc welding, using carbon electrodes to fuse metal pieces.

Throughout history, welding has evolved to meet people’s growing production needs. And today, we are on the cusp of exciting innovations in welding technology. For instance, a revolutionary latest welding technology can offer up to ten times the precision, strength, and reliability as traditional welding techniques. It can fuse dissimilar metal workpieces in a few seconds with minimal thermal distortion. This technology is known as laser welding.

The State of Laser Welding Technology

In hopes of outlasting today’s cutthroat market, manufacturers seek innovative measures for faster production, higher precision, and better weld quality. Traditional arc-based methods like TIG and MIG are still widely used, but they lack the versatility and strength to meet the rapidly growing demand and high-volume requirements of the automotive, aerospace, medical device, and electronics industries.

For this reason, many firms have started to invest in laser welding, an advanced welding method that utilizes highly concentrated laser beams to fuse metals. A laser can deliver energy in a localized beam, so the heat-affected zone (HAZ) is small. This minimizes warping and thermal distortion of parts, compared to MIG/TIG welding that spreads heat over a wider area and induces significant stress in the workpiece.

Furthermore, you can focus a laser beam to tiny spots (around 0.1 mm radius) for extremely precise welds on delicate components. Most laser welding machines also come with ergonomic and intuitive controls, which make them easy to use, even with complex projects and workpiece geometries. On the other hand, traditional MIG/TIG welding creates larger weld beads and relies mostly on operator skill, so they usually have less fine control and produce rougher and bulkier weld seams.

What Does the Future Look Like?

Laser welding’s next chapter comes with rapid progress in its methodology and impact, thanks to endless innovations in its hardware and software components.

For instance, some of the latest welding technologies use high-performing fiber laser modules and advanced beam-shaping optics to produce a narrower, more stable arc. Meanwhile, real-time weld-monitoring software and AI-based control platforms can automatically adjust laser power levels, speed, and focal position to prevent defects.

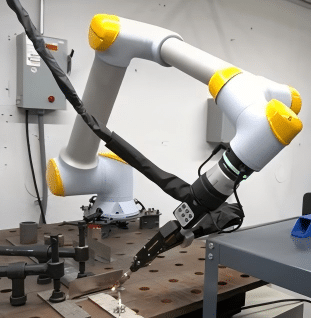

We can also anticipate the integration of advanced automation and robotics to ensure precise weld paths with minimal deviation. For example, future electric vehicle batteries might require repeatable seams with at most ±0.05 mm deviation to prevent micro-cracks, thermal runaway risks, and current-transfer loss. This needs highly precise automated robots, as human operators cannot weld neatly under these ultra-precise conditions.

Technical Challenges and Solutions in Laser Welding

To maximize laser welding’s potential, it is crucial to understand its common technical challenges and ways to overcome them. For example, excessive heat input can distort thin components, and any slight deviation in the optimal laser parameters can cause cracks or pores. Hence, the laser welding machine and its operator must observe precise control of energy delivery to prevent any metallurgical issues.

Fortunately, recent innovations in welding beam shaping and modulation can solve typical laser welding limitations., Adjustable beam profiles, dual-spot configurations, and high-frequency power modulation can direct sufficient energy exactly where the joint requires support. These methods reduce spatter, refine penetration, and improve seam uniformity on complex geometries or dissimilar metal pairs.

Denaliweld is one of the global providers of laser welding solutions that overcome welding challenges through proprietary technology. For instance, Denaliweld’s COBOT series features one-click operation to activate pre-set optimal laser parameters to help operators achieve consistent and precise results. No need to worry about overheating as this proprietary technology ensures that the beam application produces heat sufficient to melt and fuse your workpieces.

Environmental and Safety Advances in Latest Welding Technology

Laser welding is a cleaner manufacturing practice with a smaller environmental footprint than conventional arc methods. The process consumes less energy, generates fewer fumes, and eliminates flux, filler wire, and excessive consumables. Manufacturers reduce scrap volume and post-processing waste, which leads to lower emissions and cleaner workspaces across large production cycles.

Safety standards in laser welding have also advanced recently. Modern laser facilities now rely on improved shielding architecture, fail-safe interlocks, and intelligent detection systems that prevent accidental beam exposure.

Economic Impact and ROI of Latest Welding Technologies

Laser welding is far faster than conventional arc systems. In fact, laser welding is around 10 times faster than MIG welding and 40 times faster than TIG welding. The reason is that the process generates less heat, requires fewer passes, and can be highly automated. Furthermore, this method uses less scrap and shorter production cycles, which translates into a larger return on investment in both low and high-volume production environments.

It is indeed costly to acquire a laser welding machine. Some entry-level models cost at least USD 20,000. But keep in mind how laser welding can operate at higher speeds compared to traditional welding methods, thereby reducing production time. Also, the machines require less maintenance and have lower failure rates, which guarantees fewer operational interruptions. Hence, the laser welding adoption can be cost-effective in the long run, with its benefits outweighing its significant upfront cost.

Stay on Top of Latest Welding Technologies With Denaliweld’s Smart Laser Welding Solutions

Firms continuously strive to achieve superior quality products in high volume. And to meet this demand, welding technologies evolve rapidly.

Amongst the latest welding technologies, laser welding offers unmatched precision, strength, and cost-effectiveness that levels up the turnaround rate and productivity of any industrial manufacturer. It can also fuse dissimilar metals, work around complex metal geometries, and generate welds with minimal heat distortion.

Denaliweld is an industry leader that shapes the future of laser welding solutions. We invest in comprehensive R&D to deliver cutting-edge in-house laser sources, control systems, coolers, and setups. All of our advanced laser welding solutions have passed SGS, CE (MD, EMC), WPQR certification, and C-Test, which ensures their world-class quality and compliance with stringent international standards.