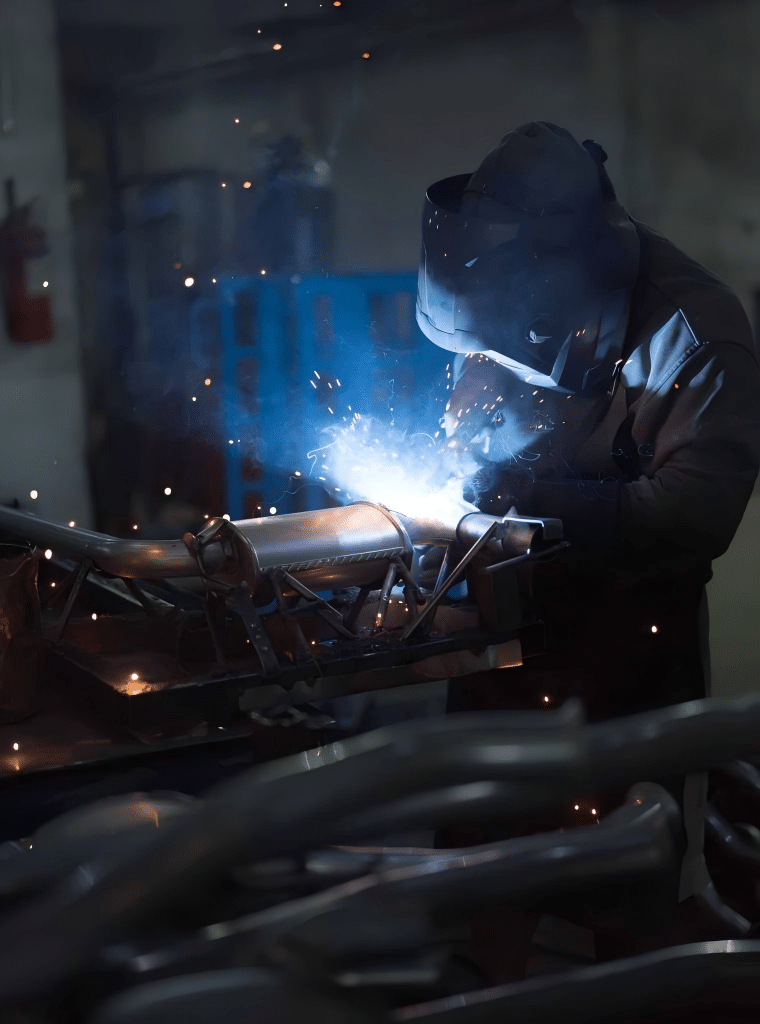

Weld spatter: the bane of novice and long-time welders alike. These unsightly metal droplets are not only an aesthetic nightmare but also leave an impression that the weld is poor, weak, and unclean.

In hopes of helping you achieve top-quality welds, we discuss what causes weld spatter. We also expound on other common welding mistakes, such as poor joint preparation and insufficient ground.

What Causes Weld Spatter?

Weld spatter forms when drops of hot molten metal splash from the weld and reach the workpiece and its surrounding area. As these molten droplets cool, they form tiny, round, and bulging balls where they land.

Traditional welding techniques like MIG and TIG welding are highly prone to spatter formation. Meanwhile, advanced methods like laser welding produce minimal spatter.

Weld spatter is usually caused by any of the following:

Incorrect Welding Parameters

Weld pool disturbance is a primary culprit of spatter formation. For instance, excessively high amperage or a low voltage setting for the wire makes it difficult to melt the wire and pool. This results in a pop that leads to spatter formation (many welders call this phenomenon “arc explosion”).

Contaminated Workpieces

Some contaminants present in the base materials, such as grease, oil, and rust, also burn and vaporise during the welding process. The vaporized contaminants expand the gas quickly, which disturbs the molten weld pool. This causes the droplets to be ejected as spatter.

Wrong or Insufficient Shielding Gas

Shielding gas protects the weld pool from atmospheric contamination. Hence, the incorrect and insufficient use of shielding gas can result in weld contamination and spatter formation.

For instance, using pure CO₂ as a shielding gas in stainless steel MIG welding, instead of a recommended argon-CO₂ mix, can lead to excessive spatter because pure CO₂ produces a harsher and less stable arc. Meanwhile, if the shielding gas flow rate is set too low (e.g., <15 cubic feet per hour), ambient air can mix with the shielding gas, which introduces oxygen and nitrogen into the weld area.

Worn or Incompatible Consumables

Using an electrode that is too small or huge for the intended weld current can create an erratic arc and cause spatter. Another example is welding aluminum with a steel wire, which is incompatible and will not only cause spatter but also result in a weak and compromised weld.

Common Welding Mistakes Beyond Spatter

Aside from spatter formation, weld quality is also compromised by other errors. For instance, poor joint preparation or when the surfaces to be joined are not properly cleaned, beveled, or aligned can lead to weak welds or failed fusion.

Improper torch angle and travel speed are also common problems. Holding the torch at the wrong angle or moving too quickly or too slowly can cause uneven bead shape, undercutting, or weak penetration.

Poor or a lack of equipment maintenance is also a common issue. If welding machines or cables are not inspected and maintained regularly, issues like erratic arcs, overheating, or poor electrical connections can happen and compromise the weld quality.

How to Avoid Spatter in Welding?

It is impossible to achieve a 100% spatter-free weld. But there are various measures that can minimize them, such as

(1) Parameter optimization: Configure the welding parameters to a “Goldilocks zone” in terms of current, voltage, and wire feed. Note that the optimal parameters depend on the workpieces’ material type and the specific project requirements.

(2) Thorough workpiece cleaning: Before welding, make sure that all workpieces are clean. You may wire brush or grind to eliminate thick contaminants, or use solvent cleaning with acetone to remove oils and grease from the metal surface.

(3) Select the correct shielding gas and maintain proper flow rates: For instance, Argon is typically used for a stable and clean weld arc. Carbon Dioxide is common in deep penetration welding. Helium is used in applications that require high temperature settings.

(4) Use “fresh” and appropriate consumables: Use high-quality welding rods and wires that are kept in dry and clean conditions. You can melt consistently and minimize erratic deposits if the consumables are “fresh”.

(5) Observe proper welding techniques: Hold the torch at the recommended angle and maintain a steady hand to achieve a uniform metal fusion and minimal spatter. Controlled movement also helps avoid abrupt changes in the weld pool, which can cause droplets to scatter.

Preventive Measures for Other Welding Mistakes

As with spatters, other typical welding mistakes are also preventable. For instance, you can measure and mark each workpiece before assembly to ensure precise alignment. Use clamps, jigs, or tack welds to hold components in place during welding. Do not forget also to check for gaps or misplacement with a straightedge or square, and adjust as needed before beginning the weld.

Regular and proper maintenance is also vital. Always clean the torch nozzle and contact tip after each use to remove slag or debris. Moreover, replace worn or damaged cables, liners, and contact tips regularly to maintain steady current flow.

Achieve Spatter-free Welding With a Smart and High-performing Advanced Welding Equipment

There is no better way to prevent a problem than understanding its root cause. In this article, you learned various causes of weld spatter and other welding mistakes, as well as how to prevent them to achieve a top-quality weld.

Yet there is one more approach that can significantly reduce welding errors and spatter formation. This is the adoption of modern welding technologies, such as laser welding. Laser welding uses a highly concentrated beam that precisely hits the weld area. Its top-level precision creates a small heat-affected zone that guarantees minimal spatter formation.

For more information about laser welding, visit Denaliweld. We are a global manufacturer of advanced laser welding machines for a wide range of applications in automotive, electronics, aerospace, and medical device industries. All of our products are CE/SGS/WPQR-certified and bolstered by seasoned laser engineers and industry experts.