DENALIWELD

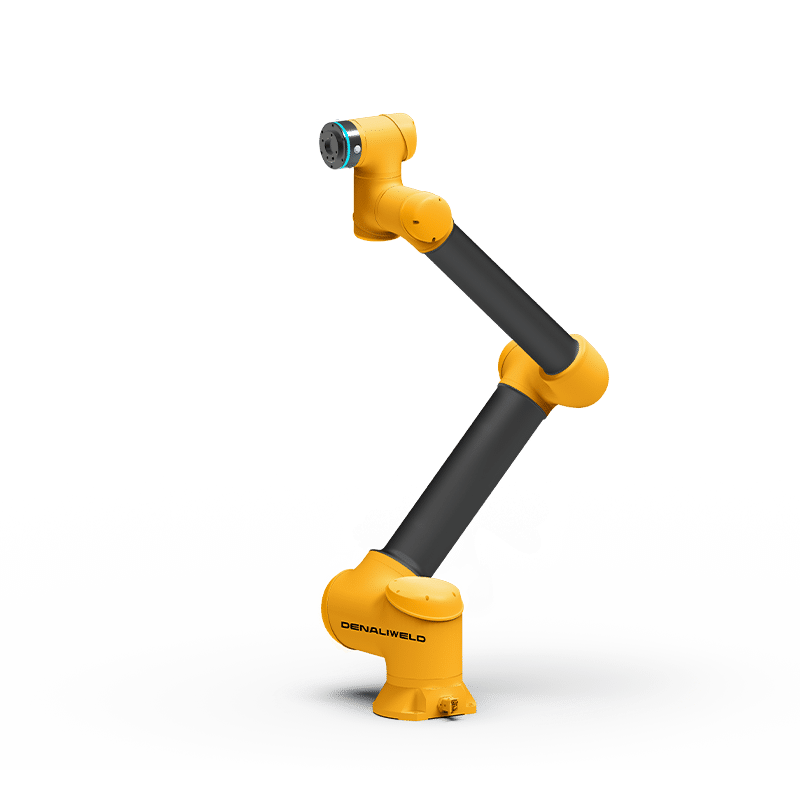

DenaliWeld COBOT Welding System

The DenaliWeld COBOT Welding System combines advanced automation with user-friendly technology, delivering precision, efficiency, and seamless integration for modern manufacturing environments.

- Independently developed: Our independently developed welding robots and welding control systems are compatible with both air-cooled and water-cooled Denaliweld models, providing flexible integration across multiple platforms.

- Modular Design for Easy Maintenance: Engineered for uncomplicated maintenanceand quick repairs, reducing downtime and increasing productivity.

- Intelligent Cobot Programs: Features a simple user interfacewith pre-set parameters for one-click operation, making it easy for operators to achieve consistent and precise results.

- Welding Data Acquisition System: Monitors and records welding performance, assisting in operation trackingand cost calculations for optimized workflows.

- Seamless Automation Integration: With one-click switching, easily transition between Cobot and robot automation using the DENALIWELD ROBOX™ system.

- Wide Compatibility: DENALIWELD welding machinesare compatible with most leading Cobot manufacturers, ensuring versatility in industrial applications.

- Advanced Automatic Welding Head: Utilizing the Automatic Welding Head (GCR 5/10/16)enables real-time power adjustments throughout the welding process for enhanced precision and quality.

- Optional Seam Tracking System: Available with an optional seam tracking system, allowing for precise weld alignment and improved accuracy.

Features and Configuration

DenaliWeld Collaborative Robots (Cobots) are designed to deliver precision, efficiency, and ease of use, providing a cost-effective solution to elevate your welding operations. With their lightweight, flexible, and intelligent design, these cobots offer best-in-class performance to meet the demands of modern manufacturing.

- Lightweight and Flexible Design: Easy to integrate into various production lines, providing versatile welding solutions for a wide range of applications.

- Intelligent and User-Friendly Operation: Operators can quickly program the cobots for specific welding tasks, allowing staff to focus on other critical activities and increasing overall productivity.

- Enhanced Speed and Safety: With industry-leading operating speeds and advanced safety features, DenaliWeld cobots ensure efficient production while maintaining a safe working environment.

- Cost-Effective Investment: Offering affordable automation without compromising quality, DenaliWeld cobots deliver a high return on investment by reducing labor costs and increasing output.

- Maximum Operational Flexibility: Seamlessly switch between manual operation and automated welding, allowing for efficient workflow management and adaptability to changing production needs.

Independently developed welding robots and welding control systems

DenaliWeld independently developed welding robots and welding control systems, which are jointly tested to ensure optimal performance, reliability, and functionality to meet evolving user needs. We offer a wide selection of collaborative robot models, creating flexible and efficient automation solutions.

- Full compatibility: Compatible with air- and water-cooled DenaliWeld models, allowing for flexible cross-platform integration.

- Proven Performance: Rigorous joint testing ensures higher precision, smoother operation, and consistent results in real-world welding applications.

Seamless Transition from Manual to Automated Welding

DenaliWeld collaborative robotic welding solutions are designed for maximum flexibility, featuring handheld welding torches that enable a smooth transition between manual and automated welding.

- Quick Switching Mechanism: The laser welding machine is equipped with a manual/automatic switching button, allowing operators to easily toggle between handheld and robotic welding modes.

Enhanced Flexibility: This dual-functionality design supports customized workflows, enabling users to adapt quickly to changing production demands while maintaining precision and efficiency.

Simple and Easy to Use

DenaliWeld collaborative robotic welding systems are engineered for simplicity, offering quick integration and hassle-free setup across a variety of robotic welding applications.

- Fast Installation: Designed for rapid deployment, allowing users to get up and running quickly with minimal downtime.

- User-Friendly Interface: Intuitive controls ensure easy operation, making it accessible for both experienced professionalsand new operators.

- Versatile Application: Compatible with various robotic welding tasks, delivering consistent performance across different production environments.

| Technical parameters | Item | Denbot5-910 | Denbot10-1300 | Denbot16-2000 |

| Robot body | Maximum Load | 5kg (11.2lb) | 10kg (22.05lb) | 16kg (35.27lb) |

| Number of axes | 6 | 6 | 6 | |

| Maximum speed at the end | 3.6m/s (11.81ft/s) | 3.8m/s (12.47ft/s) | 3.5m/s (11.48ft/s) | |

| Maximum linear velocity at the end | 1.5m/s (4.92ft/s) | 1.5m/s (4.92ft/s) | 1.8m/s (5.91ft/s) | |

| Effective working radius | 917mm (36.1in) | 1300mm (51.18in) | 2000mm (78.74in) | |

| Repeatability | ±0.02mm | ±0.03mm | ±0.05mm | |

| Power consumption | ≈200w | ≈400w | ≈600w | |

| Installation method | Ground based、Inverted type、cantilever type | |||

| IP Grade | IP54/65 | |||

| Ambient temperature | '-10℃ - 50℃ | '-10℃ - 50℃ | '-10℃ - 50℃ | |

| Storage temperature | '-40℃ - 55℃ | '-40℃ - 55℃ | '-40℃ - 55℃ | |

| End I/O port | 2DI、2DO、EtherCAT、RS485 | |||

| Robot packaging size | 698x588x450mm (27.48x23.15x17.72in) | 958x508x516mm (37.72x20x20.31in) | 1465x516x472mm (57.68x20.31x18.58in) | |

| Net weight | 22kg (48.5lb) | 37.8kg (83.33lb) | 60kg (132.28lb) | |

| Control cabinet | Input power supply | '100-240VAC 47-63HZ 10A | '100-240VAC 47-63HZ 10A | 220-240VAC 47 -63Hz 10A/100-200VAC 47-63HZ 16A |

| IP Grade | IP44 | IP44 | IP44 | |

| Communication interface | TCP/IP,Modbus/TCP,Profinet(Slave From),Ehernet/IP(Slave From),CAN,RS485 | |||

| IO interface | 16DI, 16DO (PNP,24V/Max 500mA) Configurable 8DI/8DO | |||

| Size | 410x306x292mm (16.14x12.05x11.5in) | |||

| Weight | 13.6kg (29.98lb) | 13.6kg (29.98lb) | 13.8kg (30.42lb) | |

| FlexPendant | External dimensions (Excluding grip handle) | 295x225x45mm (11.61x8.86x1.77in) | ||

| IP Grade | IP54 | IP54 | IP54 | |

| Screen size | 10.4 in | |||

| Screen resolution | 800*600@60HZ | |||

| Weight | 1.3kg (2.87lb) |

Why Choose Us.

DenaliWeld Advantage

Our Services.

We Provide Best Services

Laser Equipment Manufacturer

DenaliWeld, a globally recognized laser equipment manufacturer, harnesses cutting-edge proprietary technology to dominate the laser welding industry, consistently delivering unmatched precision and groundbreaking innovation to our worldwide client.

Local Services

Based in Illinois with 4 global offices, our local teams ensure fast response and professional 24/7 service after your purchase with fair laser welder cost.

Certification

Machine passed SGS,CE(MD,EMC),WPQR certification &c test.

Research and Development

With our exceptional R&D capabilities, we stand among the few companies designing and manufacturing in-house laser sources, control systems, coolers, and setups, delivering precision, reliability, & tailored laser weld solutions for various industries.

Explore More

Global Services

DENALIWELD has four branches and more than 150+ dealer stores around the world. The branches can provide warehouses, inventory machines, spare parts, services, training and showrooms in local and neighboring countries.

USA

2531 Technology dr 310 Elgin IL 60124

Europe

Hantverksgatan 3 S-533 33 Gotene

Australia

1310 Boundary Road Wacol QLD 4076

Japan

中町3丁目10-11 小田原市, 神奈川県

FAQ

What Is The Warranty For DenaliWeld Machines?

We will provide a 3-year warranty on the entire DenaliWeld machine, during which the customer will receive full and prompt service. In case of non-human damage, DenaliWeld will send spare parts free of charge to replace any damaged part on the machine.

Can I Get DenaliWeld’s Services Overseas?

DenaliWeld can provide overseas service including installation, commissioning, training and maintenance to customers all over the world.

How Can I Become One Of The DenaliWeld Agents In My Country?

To become an authorized Denaliweld Agent, please submit an application through the “contact us” tab expressing your interest in representing our products in your country. We’re looking for partners with strong local market knowledge, established distribution capabilities, and a commitment to quality and customer service.

How do I contact the DenaliWeld dealer in my local city?

If you would like to contact your local DenaliWeld agent, you can send an email to [email protected], or submit a form and we will ask them to contact you directly. You can also check whether there is a local dealer through our dealer locator. We usually indicate the dealer’s contact information.

What is the shipping method for DenaliWeld machines?

If a customer orders a small machine with wooden packaging, we will deliver the machine in a consolidated container, or if the customer orders two or more machines together, we will ship them in a container and send it to the port, which will help the customer save even more money.

What about the quality of DenaliWeld machines?

We have a world-class R&D team to support the quality of our machines, and our products are CE and SGS certified, proving the advantages of DenaliWeld machines.

Machine Show and Welding Test

Our Competences

Are Confirmed By Our Customers

We’re excited to team up with @WeldingTipsAndTricks to push the limits of the DenaliWeld laser welding machine!

It’s not just about speed—it’s also about precision and quality. Want to see the results?

“The laser welder works perfectly! The welds are smooth, strong, and clean. It has significantly improved our production efficiency. Highly recommended!”

“Excellent machine! Easy to operate, very stable, and produces professional-quality results. Our team loves using it every day.”

“This laser welder exceeded our expectations. The precision is outstanding, and it’s perfect for both stainless steel and aluminum projects.”

“After switching to this laser welding machine, our productivity increased by almost 40%. The finish quality is amazing, and no post-polishing is needed.”

“Great investment! Compact design, low maintenance, and very efficient. We use it for custom metal fabrication and couldn’t be happier.”

“Excellent customer service and quick training support. The welder is powerful, reliable, and super easy to learn for new operators.”

“We’ve used many welders before, but this one stands out for its quality and consistency. It delivers clean joints with almost zero distortion.”

CONTACT US

INTERESTED IN DISCUSSING?

Customize a solution to your needs today Experience a live demo and get free samples