Denalilab

About Denalilab

DenaliLab is an exclusive laboratory created by Denaliweld Inc. dedicated to testing the quality and effect of laser welding. We have advanced X-ray equipment, penetration detection equipment, metallographic testing equipment and tensile testing equipment, etc. At the same time DenaliLab cooperate with international third-party testing agencies such as SGS and BV to provide well-founded, true and reliable welding assessments for welding effects.

X-ray detection

Metallographic testing

Penetration detection

Tensile Strength Test

DenaliLab is a non-public laboratory that only serves Denaliweld Inc. and its global dealers. Its purpose is to:

- Continuously optimize the parameter settings of Denaliweld series laser welding equipment to provide customers with accurate welding solutions;

- Provide welding tests for dealers and customers and issue welding solutions supported by evidence;

- Any dealer of Denaliweld equipment can request a laboratory to proof and test the samples free of charge.

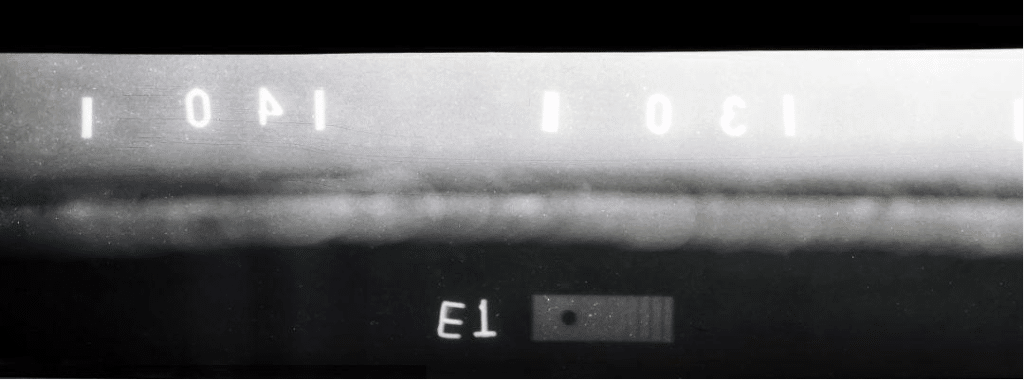

X-ray detection

X-ray flaw detection uses the difference in the degree of X-ray absorption of different material thicknesses to reveal internal defects in materials, parts and welds from films and imaging by using X-ray perspective photography and industrial television real-time imaging. Such as cracks, shrinkage cavities, pores, slag inclusions, lack of fusion, lack of penetration, etc., determine the location and size. Evaluate the quality of materials or products based on observing the nature, size and location of defects, thereby preventing major accidents caused by internal defects and poor processing of materials.

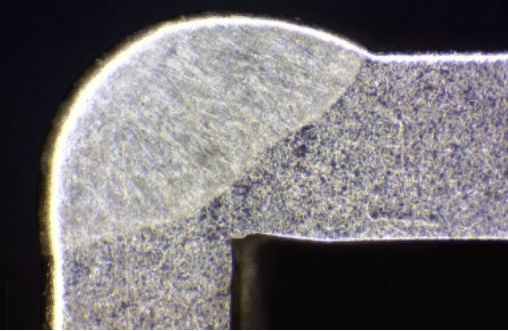

Metallographic testing

During the welding process of metal materials, various areas of the welding area undergo different degrees of thermal cycle processes, so the obtained structures are also very different, resulting in changes in mechanical properties. Metallographic analysis of welding is an important means of analyzing and identifying welding performance.

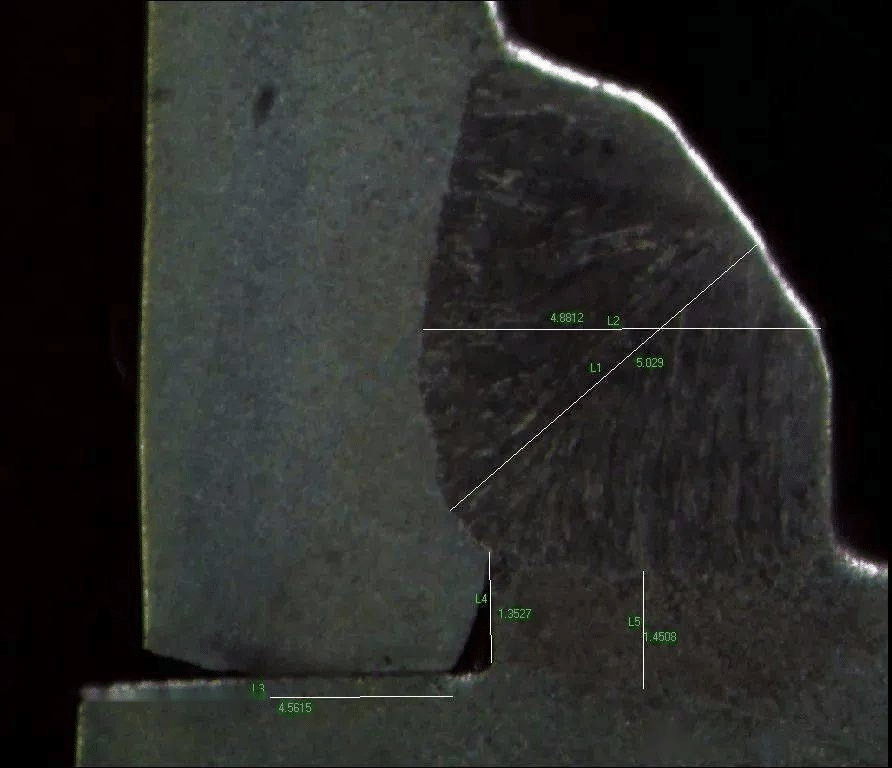

Penetration detection

It is a commonly used welding quality testing method used to evaluate the penetration depth of welds. It mainly analyzes the welding section to determine the penetration depth in the weld. A metallographic microscope is mainly used to observe the weld cross section, and the penetration can be evaluated through the length and shape of the penetration line.

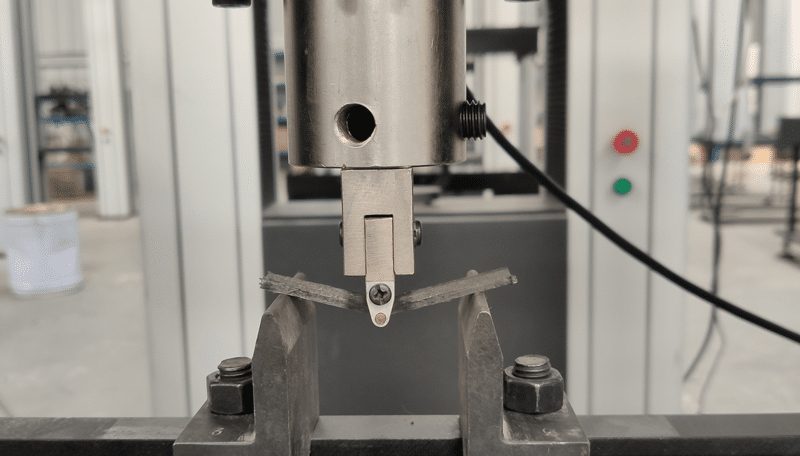

Tensile Strength Test

Welding tensile strength testing is a very important test in welding, designed to evaluate the strength and reliability of welded joints.

Welding tensile strength testing is a key step in evaluating the strength performance of welded joints.

By testing the tensile strength of welded joints, the reliability and durability of welded joints can be determined, providing an important basis for engineering design and quality control. This strength index directly determines the safety and reliability of the welded joint.

CONTACT US

INTERESTED IN DISCUSSING?

Customize a solution to your needs today Experience a live demo and get free samples