In today’s competitive manufacturing landscape, embracing technology that delivers superior speed, precision, and efficiency is important. For many fabrication and production facilities, investing in an industrial laser welding machine isn’t just a luxury—it’s a strategic necessity.

This guide is here to help you navigate the key considerations for purchasing a machine that meets your specific industry needs, ensuring a significant return on your investment by streamlining processes and improving final product quality.

Read on and determine various forms of laser welding technology.

Understanding Laser Welding Machines

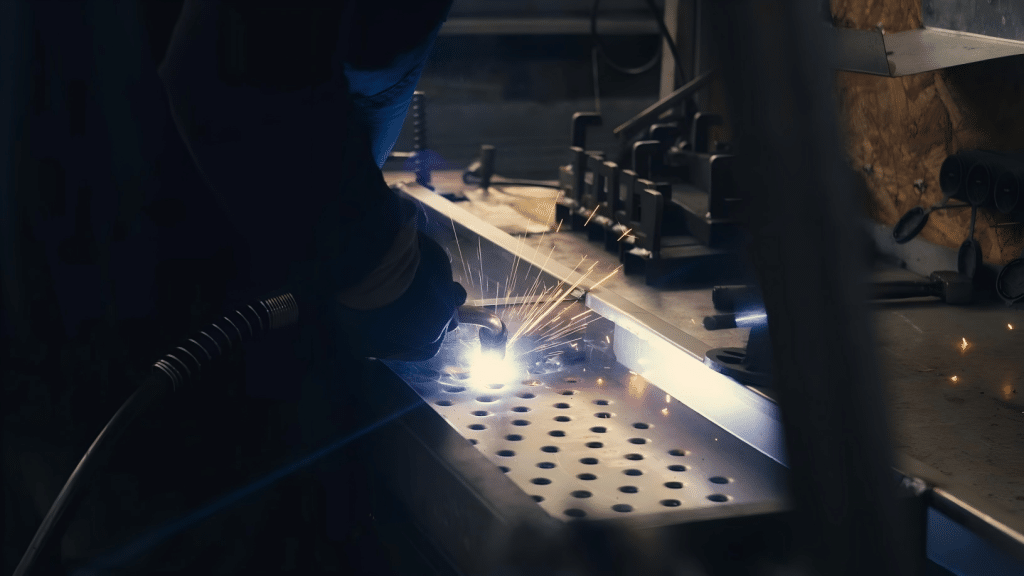

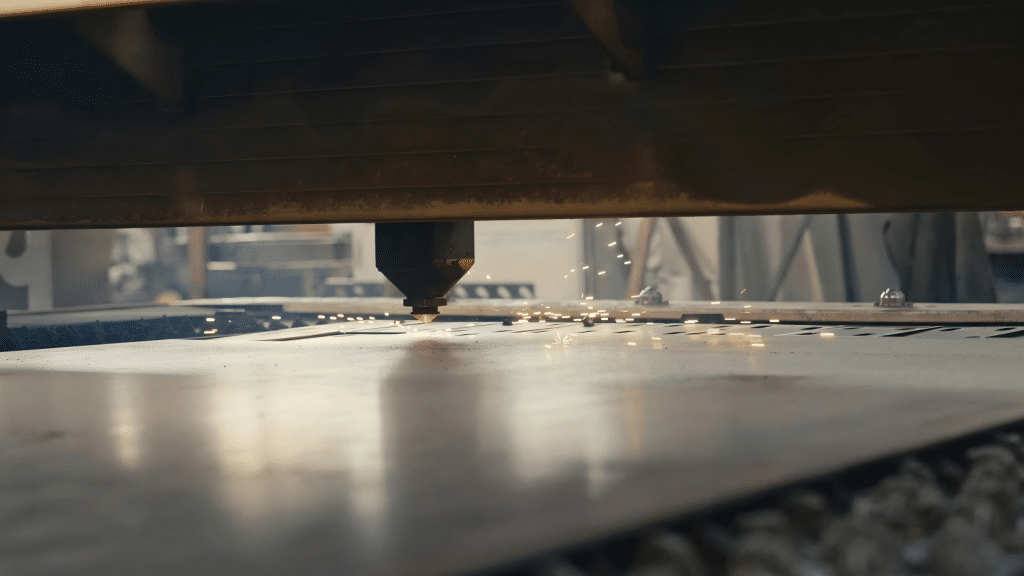

A laser welder uses a highly concentrated beam of light to fuse materials together—creating a clean, accurate, and strong connection. The main components, like the powerful fiber laser and the control and cooling system, are the parts responsible for making it work.

This welding technology is highly efficient in converting electrical energy into a powerful, concentrated laser beam, meaning you get more power and utility for less money.

Here at Deniwald, we offer a variety of machine types, from compact air-cooled units to powerful water-cooled systems designed for high-volume production. We build our innovative technology to rigorous standards, and it holds certifications from CE, SGS, and WPQR, guaranteeing the quality and safety of every machine we produce.

These certifications promise that we have tested our machines for quality, safety, and performance, giving you total peace of mind.

Key Industrial Applications of Laser Welding Machines

Laser welding machines are exceptionally versatile and have become an essential equipment for various high-tech sectors where precision and material integrity are paramount:

- Automotive:It efficiently joins lightweight aluminum body panels and seals crucial EV battery enclosures. Its precision creates strong, durable welds that maintain a vehicle’s structural integrity and crash safety.

- Aerospace: The industry uses it to create precise joints on delicate turbine blades and engine parts. Its ability to join lightweight alloys and composites with minimal heat distortion is key to building more fuel-efficient aircraft.

- Medical Devices:This technology is ideal for the medical field, as it can hermetically seal sensitive components like pacemakers and surgical tools without contamination, ensuring the highest level of sterility and performance.

- Electronics & Communication:As components get smaller, laser welding handles intricate tasks like micro-soldering circuit boards and sealing sensor housings without damaging nearby circuitry, a level of accuracy other methods can’t match.

- Mold Processing and Tool & Die Industry:It performs targeted, low-heat repairs on molds, saving companies a significant amount of money by extending tool life instead of requiring a complete replacement.

- Shipbuilding:This method creates strong, watertight seams in hulls with minimal thermal deformation, making the construction process faster and improving overall structural integrity.

- Automation: By integrating with collaborative robots, or cobots, laser welding systems achieve high throughput and consistency, safely handling repetitive tasks and freeing up your team for more complex work.

Advantages of Industrial Laser Welding Over Traditional Methods

Industrial laser welding offers many benefits compared to older common methods. When compared side-by-side to GMAW/MIG, laser welding has faster travel speeds, greater accuracy, and less heat distortion—making it great for thin materials.

As for GTAW/TIG, it comes out on top with higher welding speed, easier automation, and with a significantly smaller heat-affected zone (HAZ), making welds better in quality and preserving material strength.

When pitted against SMAW/Stick welding, laser welding is cleaner, free from spatter, and reduces dependency on manual skill, which virtually reduces the risk for operational error, ensuring consistent quality.

Another major advantage of industrial laser welding machines is their ability to connect different metals and ultra-thin materials that would commonly pose a problem with traditional welding methods.

Overall, laser welding offers speed, flexibility, and precision all in one package, helping industries and manufacturers meet modern production demands and meet tough product quality standards more efficiently.

Critical Buying Considerations for Industrial Laser Welding Machines

When investing in a laser welding machine, consider welding performance first—precision, welding speed, power adjustment, and compatibility with different materials determine real-world output. Look for easy maintenance, since downtime directly impacts productivity.

Also look for factors like ease of use, such as optics adjustment, and parts replacement—these should be straightforward to streamline the operation of the machine and make your processes more efficient and productive.

A modern software interface is also worth looking forward to: intuitive controls, real-time monitoring, and built-in safety features reduce operator errors and reduce the risk of injury for operators themselves.

Future-proofing-wise, you should also assess automation readiness, such as integration to robotic arms, CNC systems, or seam tracking. Warranty coverage and after-sales support are also important: check for parts availability, rapid and responsive customer support, and comprehensive operator training.

Also, confirm certifications and compliance (like CS, SGS, WPQR certifications) to ensure it’s on par with international standards. Finally, take note of portability and cooling options: air-cooled is good for lighter use, while water-cooled is for heavy-duty.

How to Evaluate Your Business Needs for Laser Welding

Start by identifying your production volume and required speed, as these determine machine class. Review the material types and thicknesses you need to weld, since not all lasers perform equally across different metals and alloys. Clarify your target precision and heat input limits, especially for sensitive applications.

Also, check how the machine will integrate into your current manufacturing line or automation setup, avoiding disruptions. Lastly, weigh budget versus return on investment (ROI), factoring in operating costs, power consumption, and long-term service expenses.

Why Choose Denaliweld for Industrial Laser Welding Machines

Denaliweld stands out through a myriad of reasons: our in-house R&D team and laboratory, and patented laser technologies—ensuring exceptional reliability and precision across different industries.

We have a wide product line that models your intended use. If you need an ultra-portable modular machine for flexibility, you’re looking at our JET EZ. But if you need an automated solution to maximize productivity and efficiency, our COBOT series delivers exceptional value.

With a global presence and local service teams around the globe, we provide 24/7 support and rapid parts replacements. Every machine that comes out of our product line also meets strict international safety and efficiency certifications.

We’re also backed by our loyal customers in an expansive range of industries; from automotive, aerospace, and all the way to small-scale electronics, Denaliweld has continued and continues to prove its industry-leading products and service.

Conclusion

Choosing the right industrial laser welding machine is a strategic decision that impacts productivity, quality, and long-term costs. With advantages like faster speeds, greater precision, and automation readiness, laser welding is a future-proof investment for manufacturers.

Denaliweld is ready to provide personalized consultations, demonstrations, and guidance to help you make the best decision for your business. Take the step toward reliable, efficient, and world-class welding performance with Denaliweld today!