DENALIWELD

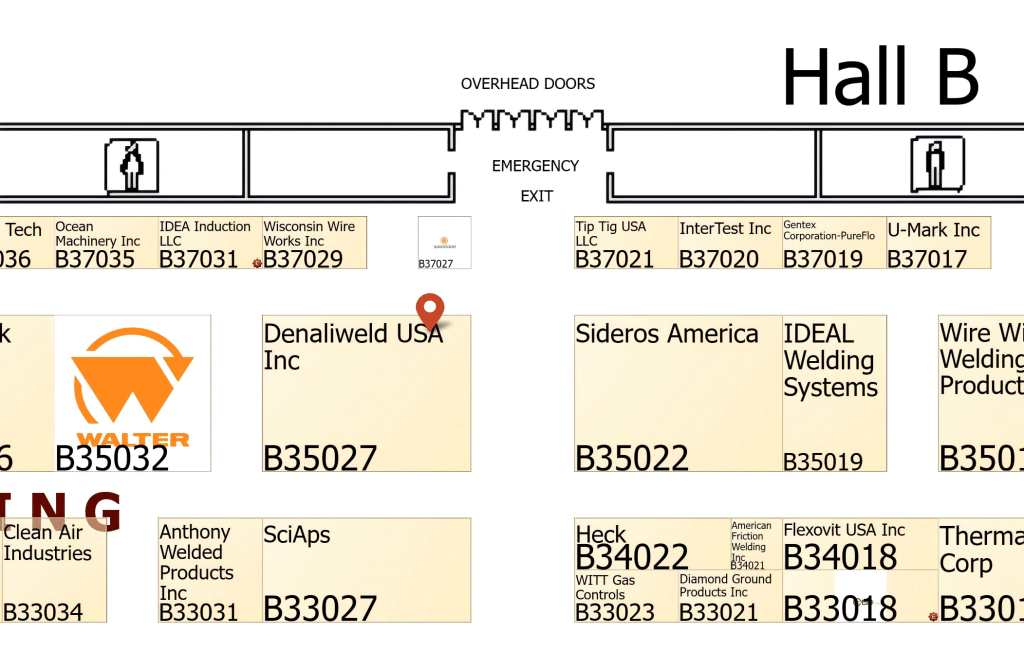

Join Denaliweld at FABTECH 2025

Date : Sep 08 – 11, 2025

Location : McCormick Place, 2301 S Martin Luther King Dr, Chicago, IL 60616

Booth : B35O27

Featured at FABTECH

- hands on demo of all series of Denaliweld Laser Welding and Laser Cleaning Machines, from 500w to 3000w

- Cobot Welding Sultions

- Highest Power of laser welding

- Safest Laser welding Solutions

At Denaliweld

We Provide Advanced & Customizable Laser Welding Solutions

METAL JOB SHOP

METAL JOB SHOP

Laser welder offers unmatched versatility for diverse materials and thicknesses with minimal heat distortion, slashing production time and costs. It adapts swiftly to various projects, making it a cornerstone of metal fabrication and boosting efficiency with every fiber laser weld.

AUTOMOTIVE

AUTOMOTIVE

Laser welder machines are essential for welding body panels, doors, frames, exhaust systems, and fuel tanks. The laser welding machine ensures precise laser welds in complex designs, enhancing safety and fuel efficiency. High-speed automation from laser fiber welding meets massive production demands, solidifying its irreplaceable role in driving automotive innovation.

BOATBUILDING

BOATBUILDING

Laser welding is widely used in shipbuilding for welding of hulls, decks, watertight compartments and other components, providing solutions with high precision, high strength and low thermal deformation, which helps to improve ship performance and production efficiency.

AEROSPACE

AEROSPACE

Aerospace demands perfection, and laser welder machines deliver. They produce clean, high-strength laser welds in exotic alloys and thin materials critical for aircraft components such as engine blades, turbine discs, cabin walls, and doors. The non-contact laser fiber weld process reduces contamination, meeting strict standards.

MOLDS

MOLDS

In the mold processing industry, laser welding machines are employed to repair and modify molds, including stamping, injection, and forging molds. They enable precise and efficient material addition and repair, extending the lifespan and performance of molds.

MEDICAL DEVICE

MEDICAL DEVICE

Laser welder machines shine by creating sterile, precise laser welds in biocompatible materials. The laser welding machine ensures consistent quality for tiny components, meeting rigorous regulations. Non-contact laser fiber welding minimizes contamination, enhancing patient safety and making it a critical tool in this industry.

Electronics & Communication

Electronics & Communication

The electronics industry depends on laser welders for delicate, high-speed laser welds without thermal damage. A laser welding machine supports miniaturization trends, joining small parts with precision for delicate components like circuit boards, chips, sensors, and displays. The repeatability of laser fiber welders ensures quality in mass production, cementing their importance in advancing communication technology.

AUTOMATED WELDING

AUTOMATED WELDING

Laser welder machines lead the charge in automated welding, integrating seamlessly with robotics. They deliver consistent, high-quality laser welds at rapid speeds, cutting labor costs and boosting output. The precision of laser fiber welding makes it ideal for automated lines, revolutionizing productivity across industries.

Meet Precise & Efficient

Denaliweld Laser Welder at FABTECH

- High Power: 3000W laser power could weld up to 3/8″

- Compact & Lightweight: Weighing only 90 pounds, the Jet Series is the smallest and lightest portable laser welder available.

- Modular Design: Easy maintenance and repair with a user-friendly modular structure.

- Versatile Functionality: Three-in-one capabilities include Welding, Cleaning, and Seam Cleaning.

- User-Friendly Operation: All parameters are pre-set for effortless, one-click operation.

- Automation Ready: Seamlessly switch to Cobot/Robot automation with DENALIWELD ROBOX™ at the touch of a button.

- Remote Control: Multiple remote control panel options are available, enabling you to conveniently manage and fine-tune machine parameters from anywhere with ease.

- Independently developed: Our independently developed welding robots and welding control systems are compatible with both air-cooled and water-cooled Denaliweld models, providing flexible integration across multiple platforms.

- Intelligent Cobot Programs: Features a simple user interfacewith pre-set parameters for one-click operation, making it easy for operators to achieve consistent and precise results.

- Welding Data Acquisition System: Monitors and records welding performance, assisting in operation trackingand cost calculations for optimized workflows.

- Seamless Automation Integration: With one-click switching, easily transition between Cobot and robot automation using the DENALIWELD ROBOX™ system.

- Advanced Automatic Welding Head: Utilizing the Automatic Welding Head (Denbot 5/10/16)enables real-time power adjustments throughout the welding process for enhanced precision and quality.

- Optional Seam Tracking System: Available with an optional seam tracking system, allowing for precise weld alignment and improved accuracy.

The DenaliWeld JET EZ is a compact, lightweight, and versatile laser welding solution, designed for precision and portability.

Patented CUAL Mosaic Laser Source: Ensures reliable continuous operation in a wide temperature range of -10°C to 40°C (14°F to 104°F) for consistent performance in diverse environments.

- Modular Design: Simplified maintenance and easy repairs with a modular structure for enhanced serviceability.

- Ultra-Lightweight & Portable: Weighing only 48.5 pounds (22 kg), the JET EZ is the smallest and lightest portable laser welder in its class—perfect for on-site and remote applications.

- Dual-Function Capability: Combines welding and seam cleaning functions in a single machine, providing efficiency and versatility for various tasks.

JET MOPA

MOPA laser cleaning devices set a new standard for innovation and technological advancement in the industry. Designed for the highest precision, stability, and efficiency, they are an ideal alternative to traditional cleaning methods. MOPA laser cleaning technology excels at processing a wide spectrum of materials, enabling effective removal of paint, rust, discoloration, grease, and oils. It’s also a reliable solution for cleaning molds, removing graffiti, preserving stone surfaces and monuments, and even renovating works of art, fabrics, parchments, frescoes, and paintings.

CONTACT US

Having questions about Denaliweld products and solutions but aren't able to attend FABTECH? Don't hesitate to contact us

Customize a solution to your needs today Experience a live demo and get free samples