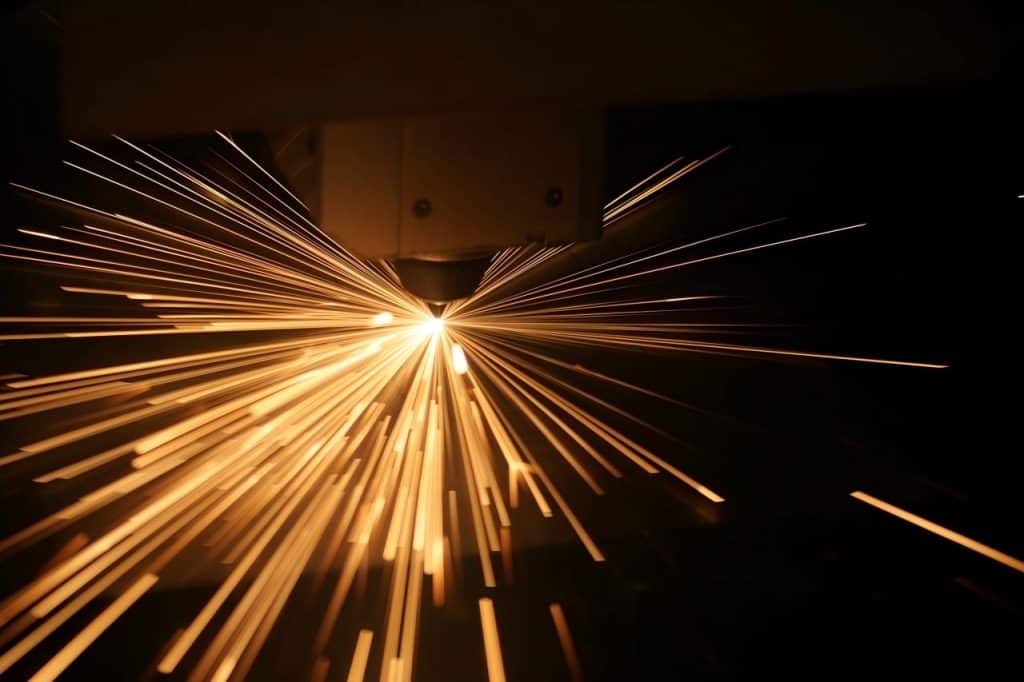

Metal fabrication is a craft that entails high-power and efficient welding techniques. For this reason, many industry leaders opt for laser welding because of its ultra-precision and minimal heat distortion that results in optimal finished metal products.

But laser welding’s success often relies on wire feeding, which is the process of augmenting filler to the welding pool using a metal wire positioned relative to the laser beam.

Let us talk about laser welding wire feeding in this article and discover the benefits of this auxiliary process.

What is Wire Feeding in Laser Welding?

Wire feeding is actually a common practice in the old-school welding techniques (TIG and MIG).In this process, a continuous wire electrode is moved into the welding arc. The wire melts and serves as filler for the joined workpieces.

Laser welding wire feeding works in the same way. A metal wire (usually made of the same material as the base material) is put near the welding area. This wire melts as the highly concentrated beam heats its surface. Eventually, the molten metal wire fills the base material and forms a high-quality weld seam.

In most cases, laser welding machines can work without a filler wire because the beam is strong enough to melt and fuse the workpieces even without additional filler material. However, wire feeding becomes essential in some cases, such as:

- When the laser-fused metals present some gaps that might compromise the product’s integrity and stress resistance. The welding wire can serve as filler material to bridge these gaps and ensure a stronger weld.

- When the workpieces are dissimilar metals. Dissimilar materials have different metallurgical and thermal properties that can cause cracks or corrosion in the weld.

Techniques and Configurations for Wire Feeding

Operators use different wire feeding techniques for specific applications to achieve a consistent and top-quality weld. Here are some common methods of wire feeding in laser welding.

TECHNIQUES

1) Cold Wire Feeding

Commonly applied in laser welding and TIG, this technique feeds a “cold wire” (a wire that is not preheated) into the welding arc.

One of the usual applications of cold wire feeding is on fused aluminum alloys. When the temperature declines after heat application, the fused metals shrink, which results in the formation of “hot cracks”. To fill these cracks, a cold wire is fed along the welded joint.

2) Hot Wire Feeding

In this technique, a welding wire is preheated before it enters the weld pool. Since the wire is sufficiently hot, the beam can swiftly melt it even with lower heat input. Thus, this approach minimizes thermal distortion and boosts welding deposition rates, which is highly beneficial when fusing thicker materials.

COMMON CONFIGURATIONS

Single vs. Dual Wire Feeding

From the name itself, single wire feeding uses one wire at a time, while dual wire feeding uses two wires simultaneously.

The single approach is simple, lightweight, and cost-effective, which makes it practical for operators performing routine tasks but on a tight budget. However, single wire feeding is not highly reliable in fusing dissimilar metals.

Dual (or twin) wire feeding has a wider welding application because of its flexibility with dissimilar metals. It can handle complex and thicker materials and significantly elevate deposition rates. However, this approach often requires a skilled operator to perform and requires higher operating costs.

Wire Feeding Angles and Positions

It is recommended to align the wire feeding position with the weld’s center line. Typically, this is around 30° to 75°. Small deviations from the center line by at least 0.25 mm can reduce the wire’s melting efficiency of up to 35%.

Advantages of Wire Feeding in Laser Welding

Some manufacturers skip wire feeding when using laser welding. But this step can actually make a huge difference to their product quality and production process.

Here are some upsides of laser welding wire feeding.

Enhanced Weld Quality: A welded joint will have uniform metallurgical strength and integrity when the metal wire is augmented as filler material directly into the welding seam. This eliminates all potential impurities in the fused workpieces, such as gaps, cracks, or distortion.

Increased Versatility: Fusing dissimilar materials often results in joint gaps and cracks upon solidification. For this reason, many operators refuse to weld dissimilar metals. With wire feeding, metallurgical gaps formed by dissimilar metals can be addressed, which improves an operator’s versatility and flexibility.

Higher Deposition Rates: Wire feeding results in improved material deposition rates, which helps in faster welding of thicker sections of the workpieces.

Reduced Thermal Distortion: The filler wire can serve as additional “padding” that helps in distributing the beam’s heat more evenly. This results in a smaller heat-affected zone (HAZ) and minimized thermal distortion.

Cost Efficiency: As wire feeding addresses most resulting flaws of a laser welding process, the need for post-welding clean-up declines. This saves the manufacturer’s time and resources in the long run.

Best Practices for Optimal Wire Feeding

Here are some recommended guidelines to perform wire feeding correctly.

1) Choose an appropriate welding wire: The ideal wire must be compatible with the workpieces and the laser welding machine to be used. Commonly used wires include stainless steel, titanium, and aluminum.

2) Polish the weld area: Prior to the positioning of the welding wire, make sure to clean the weld area to avoid contamination of the wire. Any contaminants that might touch the wire can compromise its quality.

3) Pick a consistent wire feeder: An automatic feeder with a rate of 1 to 10 meters per minute is the standard. Make sure to adjust the feed rate according to the thickness of the metals. The feeder’s accuracy must be spot on as well, even a 5% deviation from the wire feed speed set value can adversely affect the weld quality.

4) Observe careful wire positioning: It is important to lead the wire directly into the target spot with minimal deviation (<1 mm) because the laser applies the beam in a highly precise fashion (1 mm to 3 mm in diameter).

Supercharge Your Laser Welding Projects With Optimal Wire Feeding

Wire feeding is an essential measure to address any metallurgical flaw in the welded joint, especially when working with dissimilar metals. With the correct welding wire and technique, wire feeding can significantly improve your laser weld’s strength and longevity.

Denaliweld offers laser welding solutions with high-accuracy automatic wire feeders. Our wire feeders have enhanced wire capacity that supports wire feeding up to 2 mm. They can also deliver dual wire feeding for complex tasks. Equipped with a physical control button for easy operation, wire feeding becomes an easy task with a Denaliweld laser welding machine.

Visit Denaliweld and achieve optimal laser welding wire feeding.