Introduction

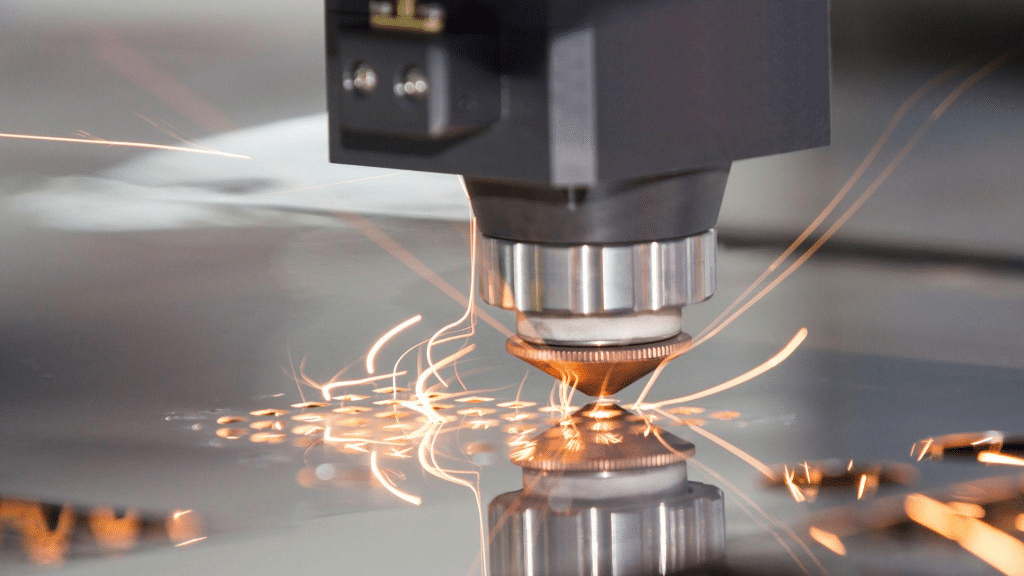

It’s the age of laser welding. From modern cars to home appliances, chances are this technology makes its components. Laser welding currently dominates today’s welding industry and for a good reason. It’s considerably more efficient, more practical, and faster compared to old-school methods like MIG and TIG.

Handheld laser welders currently take center stage. But if you’re still on the fence about whether this technology is worth the try, here are five compelling reasons why you should consider handheld laser welders for home use and business purposes.

Unmatched Precision, Strength, and Quality

Laser welding handheld machines use concentrated laser beams to melt and fuse metals together. Even with minimal heat input, laser welding can precisely penetrate up to 15-millimeter thick stainless steel and produce high-quality welds.

It’s also estimated that laser welding technology can achieve about 90% of the base material’s strength with weld seams devoid of any defect.

It’s also widely recognized that laser welding produces stronger welds compared to TIG or MIG welding methods. The high-intensity, focused laser beam generates high energy density, enabling deeper penetration and forming stronger bonds.

With the right handheld equipment, laser welding offers optimal welds with minimal distortion. Denaliweld’s Air Cooled Laser Welding Machine features a patented CUAL mosaic laser source for continuous operation that is reliable for -10℃ to 40℃ ( 14℉ to 104℉). It also has an intuitive laser control system to configure a smooth output curve for optimal weld quality.

High-Speed and Efficiency

Most high-quality handheld laser welds with 1000W to 3000W power can melt up to 12mm. This is insanely faster compared to MIG and TIG welding solutions that reach nearly one centimeter per second only.

In other words, laser welding melts materials almost immediately. The molten area also cools down and solidifies quickly, which allows rapid fusion of the components.

The impressive speed of laser welding handheld machines can significantly elevate the turnaround time of a high-volume production line. This also means that you can produce output in less time and with lesser labor.

Highly Versatile Welding Solution

Handheld laser welders work with commonly used welding materials like stainless steel, Aluminum, Titanium, and Copper. So, it’s reliable in a wide range of industrial applications.

As of this writing, laser welding is extensively used in the following:

- Automotive Industry: Joins integral vehicle parts like exhaust systems, fuel tanks, and body panels. Laser welding improves automotive performance and durability by enhancing the vehicle components’ torsional rigidity.

- Electronics: Joins intricate microelectronic components and establishes connections in a circuit board.

- Medical Industry: Assembles parts of medical and surgical equipment while ensuring a sterile and contamination-free environment.

- Aerospace: Fuses components paramount to the construction of aircraft and spacecrafts such as turbine blades, engine components, and fuselage sections.

- Commercial Appliances: Joins components of home and commercial appliances like refrigerators, ovens, washing machines, and air conditioners.

Moreover, handheld laser welders support fusion even of dissimilar materials (e.g. Copper and Aluminum) that are usually impossible with MIG or TIG. It also works well with non-metals like thermoplastics, composites, and glasses.

Cost-Effective Welding Solution In The Long-Term

Investing in a handheld laser welding machine may seem expensive at first. Entry-level models with 500W of power start at around $5,000, while mid-range 1500W machines cost at least $10,000. For larger manufacturing enterprises, high-powered machines can range from $20,000 to $150,000.

However, the long-term savings make laser welding a cost-effective choice. These machines operate at speeds up to four to five times faster than MIG or TIG welding, significantly improving productivity. Additionally, laser welders are designed for energy efficiency, reducing overall operating costs over time.

Another major cost advantage is the reduced need for consumables. Unlike traditional welding methods, handheld laser welders often eliminate the need for electrodes or filler materials. This lowers the marginal cost per unit produced, ultimately leading to higher profitability.

Beginner-Friendly Welding Method

One major drawback of MIG and TIG welding is their steep learning curve. In contrast, laser welding offers a more user-friendly experience, making it easier for beginners to learn and operate.

Most handheld laser welders have intuitive system controls, which allows users to adjust laser power and focus easily. Many models also feature integrated software that monitors temperature levels to secure safe operation throughout the welding process.

Also, handheld laser welders are designed with ergonomics in mind. Their lightweight build and comfortable grips help reduce operator fatigue and minimize the risk of strain-related injuries.

While laser welding is more accessible, it still requires strict safety precautions. Due to its high-intensity heat output, proper personal protective equipment (PPE), such as laser protective glasses and flame-resistant clothing, is essential. Operators must also be trained in emergency procedures to handle any potential machine malfunctions safely.

Supercharge Your Production Speed and Efficiency With Handheld Laser Welders

To survive in today’s competitive market, firms must increase their production with innovative solutions like handheld laser welders.

This technology provides unmatched precision and strength to deliver high-quality, distortion-free welds. It’s also significantly faster and more efficient than TIG and MIG, which helps reduce operating costs. Because laser welding is compatible with most steel and alloys, it is a highly versatile welding solution extensively used in numerous modern industries.

Whether you’re a beginner or a long-time operator, laser welding is easy to use because of its intuitive system controls and ergonomic design.

For top-quality laser welding machines that effectively slash setup time and cut operational costs, choose DenaliWeld. We are a premiere supplier of fiber laser welding machines with over 150 dealers worldwide. Our groundbreaking proprietary technology helped our global clients achieve enhanced production speed and quality in their respective industries.