R&D

Innovating the Future of Fiber Laser Technology

We are one of the few companies with R&D capacity, having developed our own laser source, control system, and chiller. Unlike others who just assemble machines or act as trading companies, we have deep expertise in laser and welding technology. We’ve conducted thousands of tests, qualifying over 120 presets, and we continuously improve our machines.

Quality Technology. Output Excellence.

We believe that the input of technology directly affects the output. Therefore, our fiber laser machine relies on self-developed core technology for continuous optimization and upgrading.

Laser Source

Self-designed laser source ensures consistent light output every time

Control System

Provides user-friendly controls and robust performance to facilitate seamless operation

Chiller

Efficient cooling system effectively cools the laser source and laser head

Setting

Proven pre-set parameters promote seamless welds

World-Class Suppliers

Other DENALIWELD components are sourced from globally recognized suppliers

WPQR

Certified weld quality control ensures optimal performance in your production plant

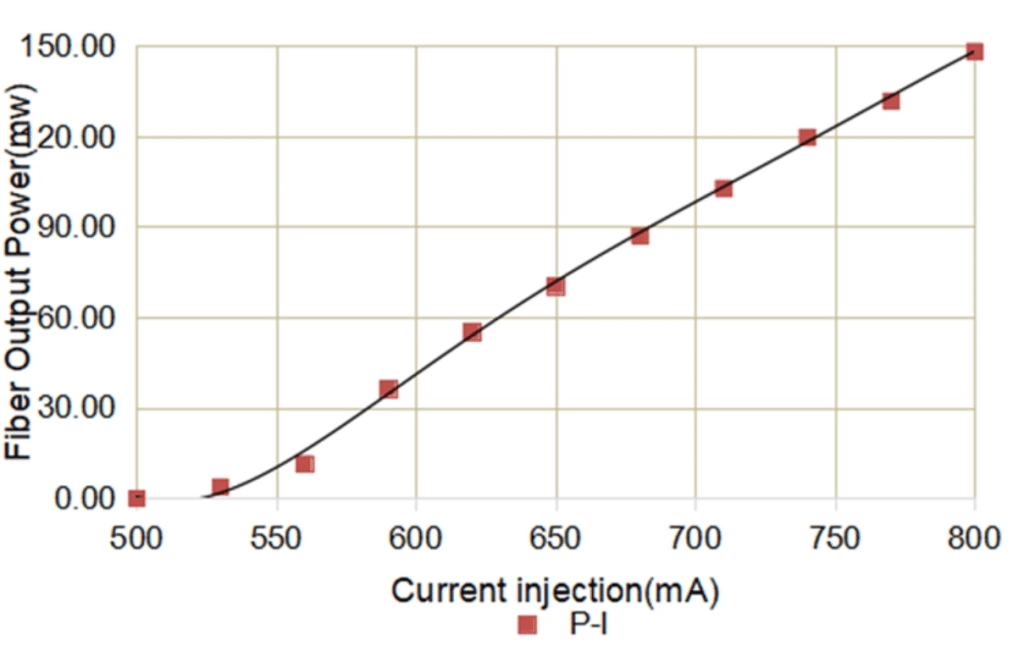

Laser Source

- Laser pump: 976nm technology laser pump(laser generator), have 45% power transfer which 915nm only have less than 20%. It achieves a smaller size but stronger in power output, and energy saving. It’s sensitive to temp, but we our techinology, the chiller could guarantee the working temp always in a safe range.

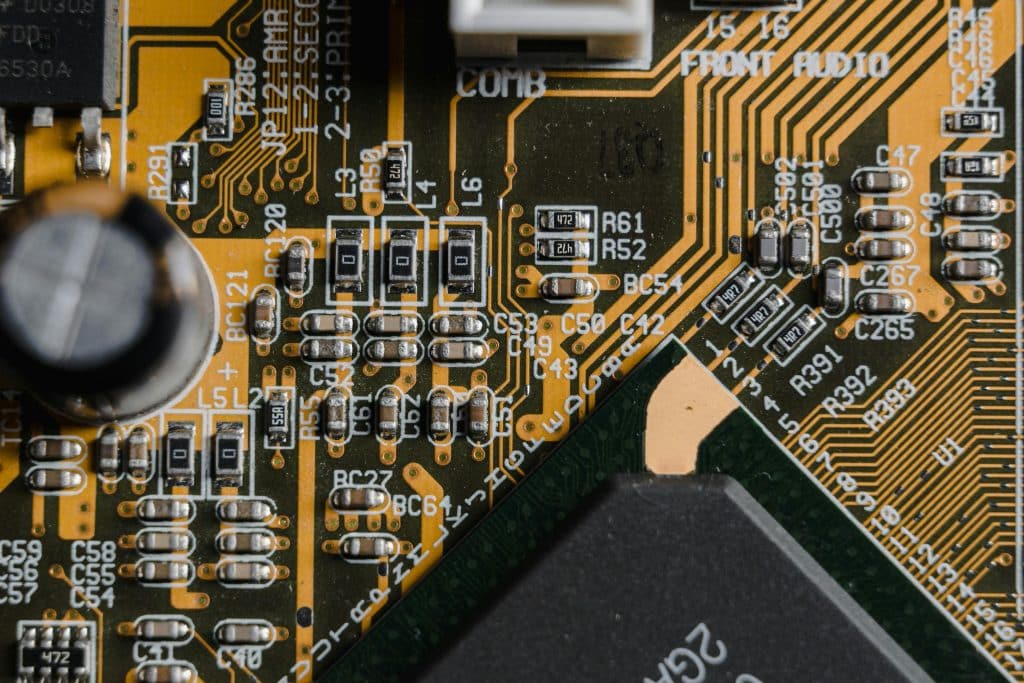

- Control Chips: 100% U.S. chips (more than 200 chips per source) are used to ensure the performance and stability of the machine.

- Control software: We use our own software to control the accurate output of the laser power. We designed the featured output curve, to provide a smart, and precise power to the welding system.

Laser Welding Control System

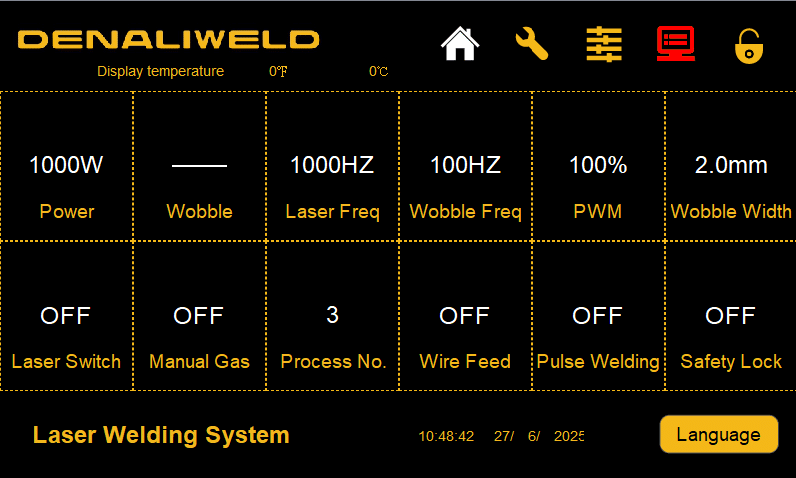

- User friendly screen:All you need are listed clearly on the main screen, and also easy to upload the pre-settings.

- All access to setting: including the centering of laser beam Check the machine status on the screen, receve alarm information, also you could even adjust the beam center in the system instead of open the motor cover and adjust the screws.

- Welding log:System allow to save and upload the welding data to monitor the welding operation. Welding time, welding power, speed ect. you could check and save. It could help the company owner calculate the cost of the welding job, and in EU countries, which apply the industrial 4.0 policy.

- Wifi remote control:All denaliweld machines (new generation) equipped with Wifi screen. With the app which could download from our webpage, client could connect the welding system screen to their cellphones, laptops and pads. No more needed walk back to the machine, especially inside of the welding station, give the welders are much easier way to operate the machine.

- Precision control of laser output:We use our own laser source, own laser control, which give us and only us the ability to make a perfect control to the output of the laser power. In all the power range, the power output is always what you get. Based on this, we mamaged to make over 120 sets of presettings for different materials, different wire size and way of welding. Each of the setting we have tested by a third party lab, and also by our own lab, and yes, we have our own lab which is nonly open for our dealers and partners. with EN-ISO and AWS standard verified.

Pre-settings With WPQR

- BV certified WPQR of welding.

which is based on the above mentioned advantages of laser source and control system. - Suitable for both EN-ISO (EU) and AWS (US) standard.

Chiller

- Water series is designed in separate modules for easy maintenance and replacement

- Accurate calculation and design of cooling capacity, providing maximum cooling effect with minimal power consumption, can meet the needs of long-term continuous operation

- All use R410a refrigerant that meets environmental requirements

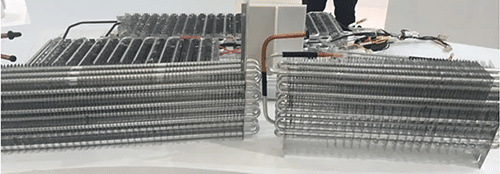

- We use the Copper+Aluminum heat exchanging system, compared with micro tube exchangers which are used on 99% of coolers in the market, our cooling unit could give much more reliable and efficient cooling to the laser source and machine, ensure the full load running of the welder.

Copper+Aluminum heat exchanging system

micro tube exchangers