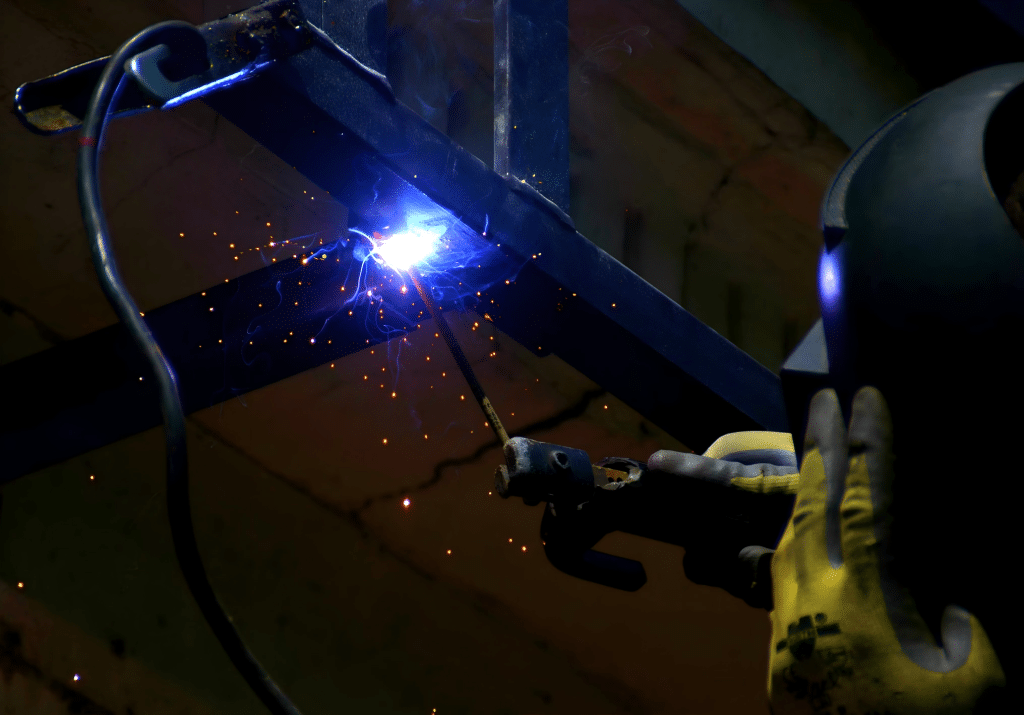

When you picture welding, you might imagine a shower of sparks flying from an arc torch—but this isn’t always the case. Laser welding is different. But when it comes to this unique method of slicing and fusing metal, most professionals wonder: Does laser welding require gas?

Left unprotected, laser welding can spoil your weld, as molten metal is vulnerable. The solution? Shielding gas. It steps in as an invisible protective umbrella, keeping contamination out and plasma under control. Read on to find out how it works

Why Does Laser Welding Use Gas?

Shielding gas is a silent partner in laser welding. Without gas, the weld becomes exposed to the environment, which can cause a multitude of problems. Here’s why shielding gas is necessary:

- It protects the molten metal: Gases like oxygen, nitrogen, and hydrogen can turn the molten metal brittle, destroying the weld. Shielding gas doesn’t react with the metal, so it keeps the weld clean as it cools.

- It prevents weld defects: Without shielding gas, oxygen and nitrogen can infiltrate your weld, causing pores, rough spatter, and micro-cracks. Surrounding the weld with a clean gas atmosphere reduces oxidation and contamination.

- It keeps the beam clear: High-powered lasers can vaporize parts of the metal, causing plasma to scatter and absorb the laser light. The shielding gas disperses this cloud to maintain the beam’s sharpness.

- It protects your equipment: Welding can be messy, especially when vaporized metal and tiny droplets can damage your focusing lens. A steady gas flow can create a protective barrier, keeping your optics clear.

However, you won’t always need to use shielding gas. For example, certain steels won’t need gases, especially for small, low-cost parts or non-critical welds. Welding inside a vacuum also eliminates the need for gas.

How Does Shielding Gas Work in Laser Welding?

When lasers melt metal, the weld pool acts like molten chocolate—it’s susceptible to its surroundings. Molten metal reacts instantly to oxygen, nitrogen, and moisture, with shielding gas acting like “bubble wrap” or a protective blanket.

How shielding gas flows also changes how the weld behaves. Argon, for example, is a heavy and calm gas, best suited for providing a smooth and stable cover. On the other hand, helium is a light and highly conductive gas, which spreads the heat more evenly and pushes the weld deeper into the metal.

Part of ensuring the shielding gas does its job is getting the right balance. Too little gas can allow air to sneak in, whereas too much gas can risk blowing the molten metal around.

Common Types of Shielding Gases Used in Laser Welding

We previously mentioned helium as one of the most reliable shielding gases, but you’ll still have your pick of the litter. Here are some types of shielding gases you can use in your laser welding project:

- Argon: Argon is an inert, affordable, and highly popular shielding gas choice. It’s best for aluminum, stainless steel, and other non-ferrous materials, as the gas keeps your weld smooth and spatter-free. However, argon is a poor heat conductor and may not penetrate the metal as deeply.

- Helium: Helium is more expensive than argon, but it’s better-suited for high-power welding on thick and reflective materials, such as copper and brass. It produces minimal plasma absorption, but it’s lighter than air, requiring higher flow rates to create a full gas curtain.

- Nitrogen: Although not inert, nitrogen can still be beneficial for stainless steel welding, as it enhances penetration and strengthens the weld metal. However, it runs the risk of making your weld brittle, so you’ll want to use it as carefully as possible.

- Gas mixtures: Using a blend of gases can be beneficial under specific circumstances. Argon-helium mixes, for instance, can tweak penetration and arc stability or fine-tune the bead profile.

Effects of Shielding Gas Parameters on Weld Quality

The type of shielding gas and how much of it you use can change the outcome of your welding project. Getting the right coverage—not too much or too little—ensures the weld surface comes out bright and clean, free of puff marks.

Select gases based on the desired shape of your weld. If you’re looking for a narrow, deep weld, use helium. Want a more stable and shallower weld? Use argon.

Next, consider flow rate. Welding too fast can scatter the laser and destabilize the weld, while blasting too much gas can whip air back into the weld pool, creating pores. It’s almost like stirring a pot too quickly—you don’t want to break your sauce or cause bubbling.

When adjusting nozzle size, gas type, and laser power, pay attention to the red flags in your weld, including porosity, spatter, and oxidation.

Advanced Technologies in Shielding Gas Application

Today’s laser welding machines don’t just fire beams. Most are jam-packed with innovative features that make shielding gas more reliable, and Denaliweld has been leading the pack.

Denaliweld’s JET series guided jet heads feature precision-engineered nozzles that ensure protection for every millimeter of molten metal. It also employs an automated flow control system to adjust gas, preventing turbulence and creating balance.

Deniwald machines further safeguard delicate parts of your weld by using inert gas to keep optics clean.

The best part? You can monitor everything, including pressure, flow, and moisture, with a Deniwald machine. It’ll alert welders to issues like low gas pressure and hidden leaks, providing ample opportunity to fix problems before they affect your weld.

Practical Tips for Selecting and Using Shielding Gas

While shielding gas is tried and tested, it can still be tricky to work with. Here are some tips for choosing and using the right gas for your project:

- Match the gas to the metal: Much like a food and wine pairing, what gas you choose will depend on what metal you’re using. Argon is a versatile choice, whereas helium is best suited for copper and brass.

- Perform regular maintenance: Remember, gas lines are prone to leaking and can collect moisture over time. Use the right regulators and test for leaks. Replace old parts as needed and store your equipment in a safe, dry space.

- Adjust the flow rate accordingly: Start with 15-20L/minute on thinner sections and move up to 30L/minute when using helium for thicker parts. Remember, gas choice and flow matter just as much as laser power and speed.

Conclusion

In laser welding, selecting the right shielding gas makes all the difference between a perfect weld and a failed joint.

If you’re looking for precision gas control and seamless integration, Denaliweld’s JET Series Laser Welding Machines are for you. They’re designed with advanced gas shielding technology that delivers smooth, laminar gas curtains over the weld pool.