Introduction

In 1917, Einstein developed a brilliant theory: atoms can release excess energy as light. Forty-one years later, that theory paved the way for the invention of the first functional laser.

Fast forward to today, the fruits of Einstein’s proposition are ubiquitous in modern industries. From commercial manufacturing, electronics, and communication to scientific experiments and medical innovations, lasers prove to be highly beneficial.

Explore laser technology in depth in this article, and learn about the basic types of lasers and their significant applications.

What is a Laser?

A laser is a device that stimulates atoms to emit a focused beam of light. The term “laser” is an acronym for “Light Amplification by Stimulated Emission of Radiation.”

To produce a laser beam, an external source such as an electric current, lamp, or flash tube generates energy that excites atoms. These particles reach a “higher energy” state but eventually return to their normal state, releasing light. Subsequently, stimulated emission occurs, where the emitted light excites more atoms, producing light beams of the same wavelength.

Through stimulated emission, light amplifies and bounces between mirrors within an optical cavity. A portion of this light “escapes” and forms a focused laser beam.

The Most Common Types of Lasers

There are five different types of lasers based on their gain medium, the material that amplifies light through simulated emission. It’s imperative to understand the mechanisms of these laser types for the correct application of their capabilities.

Solid-State Lasers

This laser type uses a solid gain medium such as glasses or crystals doped with a rare earth element (e.g. chromium or neodymium) to produce a laser beam.

Solid-state lasers are optically pumped, which means that an external source such as flash lamps is used to excite atoms in a medium. Optical pumping is cheap but it produces a high-powered beam with a moderate lifetime.

Common examples of solid-state lasers are:

- Small diode-pumped Nd: YAG lasers: A versatile and efficient solid-state laser that uses aluminum garnet (YAG) and neodymium ions for laser operation. It’s used in some surgical procedures, plastic or metal material alterations, and three-dimensional environmental mapping via LIDAR technology.

- Ruby laser: A solid-state laser that utilizes a synthetic ruby crystal as the gain medium. The ruby laser is the first functional laser developed by Theodore Mainman in 1960.

Gas Lasers

In gas lasers, a single or mixture of gases such as carbon dioxide, helium, neon, or argon is the gain medium. Unlike solid-state lasers, gas lasers are pumped electrically using a high-voltage electrical discharge.

One main advantage of gas lasers is their high-volume gain medium that enables a high concentration of excited particles, resulting in higher power output.

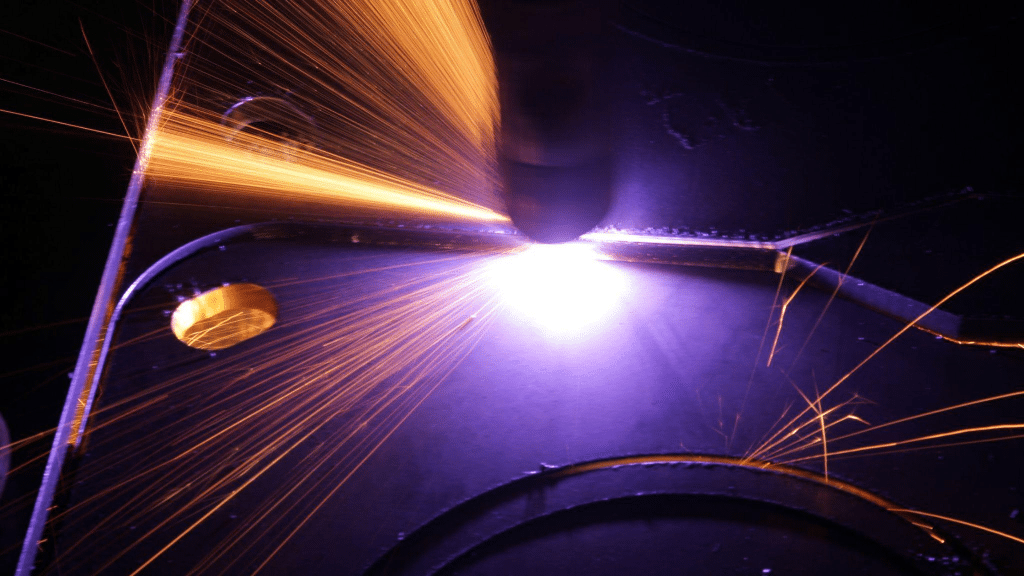

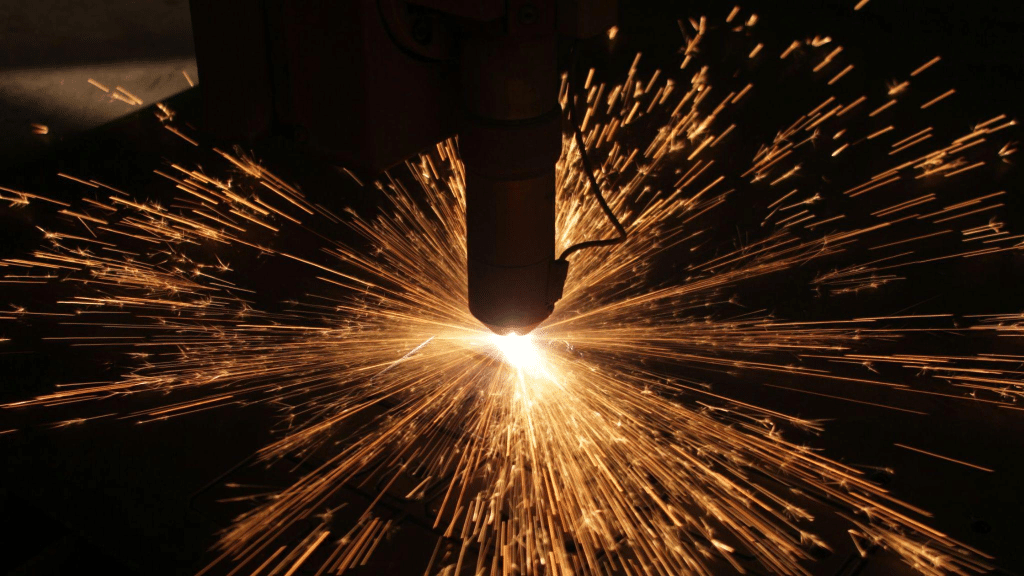

Carbon Dioxide (CO2) lasers are one of the most prominent gas lasers. It’s primarily used in industrial cutting and welding. It’s also commonly used in infrared holographic applications. Meanwhile, argon and nitrogen gas lasers are widely used in scientific and medical applications.

Semiconductor Lasers

Also known as laser diodes, semiconductor lasers use semiconductors such as indium gallium arsenide (InGaAs) or gallium arsenide (GaAs) as the gain medium.

Semiconductor lasers have positively-negatively (PN) charged junctions which carry out a process called carrier recombination that releases energy in the form of photons. The emitted photons then trigger a stimulated emission process which produces a focused beam.

This type of laser is currently applied in different industrial and commercial devices such as laser pointers, laser printers, laser scanners, and barcode readers.

Fiber Lasers

A fiber laser uses an optical fiber doped with rare earth elements like thulium, erbium, and holmium. It produces high power output, beam quality, and energy efficiency, which is ideal for high-volume production lines.

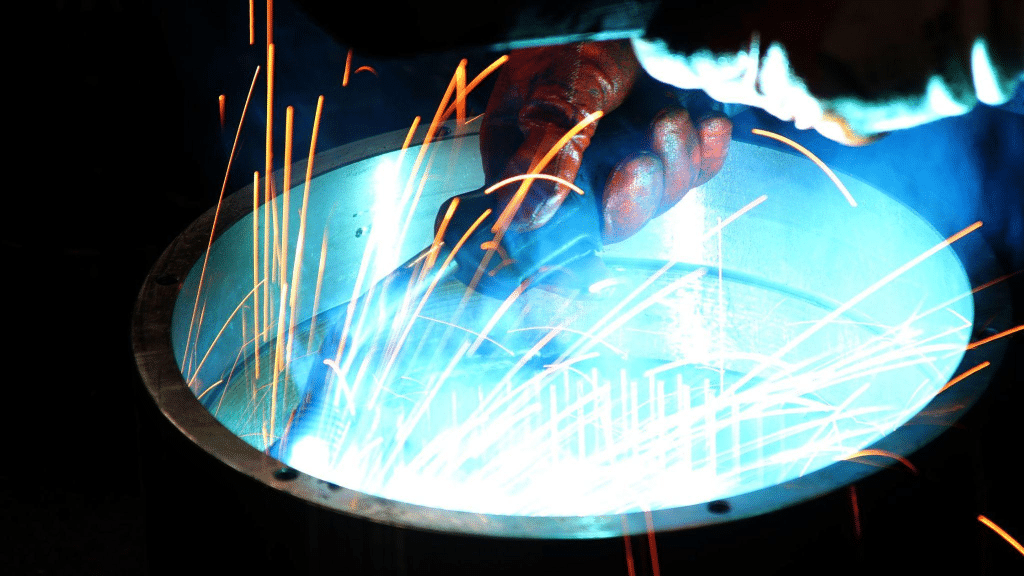

A notable fiber laser application is laser welding machines such as Denaliweld’s Air-Cooled Laser Welding Machine, which produces laser power of up to 2000W and an impressive welding speed of around 90 cm per minute. It delivers high power output at a conservative energy level and a safe temperature range. Denaliweld features innovative and user-friendly control software for optimal output curves that provide smart and precise laser power.

X-ray Lasers

Compared to the previous types of lasers, X-ray lasers do not emit visible light. Instead, it produces an invisible X-ray light to the naked eye. This technology uses electrons that achieve high kinetic energy through acceleration. The speed of these particles can reach about 99% of the speed of light, which then produces an X-ray laser beam.

The gain medium of X-ray lasers is usually a plasma formed by ionizing gases. It’s also common to use a magnetic field formed by an undulator or a device that facilitates the production of highly collimated beams of electromagnetic radiation.

X-ray lasers are rarely applied in commercial production because of their relative complexity. They are more common in the scientific field such as in structural biology, astrophysics, and materials science.

Applications of Laser: From Industrial Use to Medical Innovations

Due to its high-intensity power, reliable energy efficiency, and on-point precision, the laser becomes significant in elevating the performance of various industries such as:

- Manufacturing: Lasers can mark, cut, weld, and clean materials with absolute speed and precision. This technology fast-tracks the production process and drives operating costs down.

- Scientific Discoveries: Lasers are highly useful in observing elementary particles and their properties. For instance, the Brownian motion of particles is observable using lasers.

- Military: Pinpoint target acquisition becomes possible through LIDAR technology powered by lasers. Night reconnaissance missions become safer and more convenient as well with laser-powered illuminators. Lasers can also dispel warheads by efficient missile damage.

- Medicine: Lasers are extremely reliable in surgeries, such as kidney stone removal. They can also assist in diagnostic processes. For example, fiber-optic endoscopies can aid in detecting stomach or intestinal issues ulcers.

Harness the Power of Laser Technology With Denaliweld

With impressive output power, unmatched precision, and top-level energy efficiency, lasers have been crucial in the advancement of modern technology. Whether they come as a solid-state, gas, semiconductor, fiber, or X-ray laser, their capabilities can positively impact an industry or scientific endeavor.

Amongst its countless applications, lasers are now the trend in modern industries. It can speed up production about ten times compared to traditional welding methods at lower operating costs.

Experience top-quality laser welding with Denaliweld. We are a world-class fiber laser welding machine manufacturer with innovative and CE/SGS/WPQR-certified laser welding solutions for different industrial needs. Our cutting-edge proprietary technology is ready to step up your production capabilities and speed. Choose Denaliweld today.