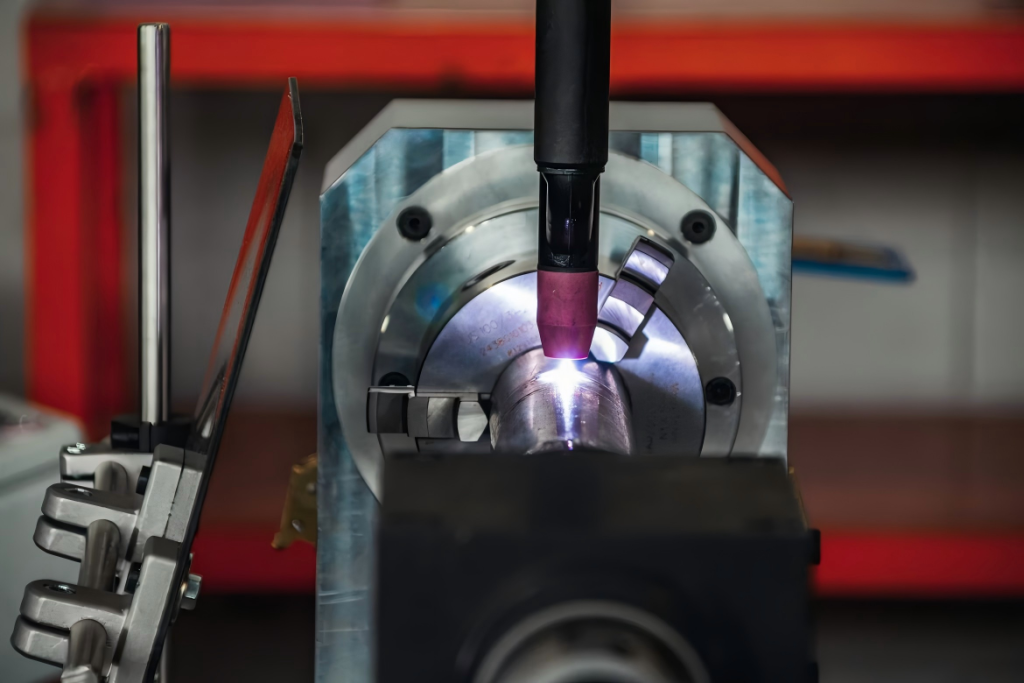

Precision cobotics in welding is a welding method that combines the best of human skill with robotic consistency. With this welding method, the result is a uniform, consistent, and high-quality weld.

TIG welding is renowned for its accuracy, but it’s also popular for being too demanding, as perfect angles, ultra-steady hands, and consistent heat are required. With cobots, or collaborative robots, welders now have a solution to ensure repeatable, high-quality welds while still allowing for actual human oversight.

But keep in mind that cobotics don’t replace welders; they actually complement them. By reducing fatigue and eliminating human inconsistency, cobots can maintain quality across long-hour shifts and high-volume production.

How Precise is Precision Cobotics?

Modern precision cobotics systems are tremendously accurate, with many advanced systems demonstrating repeatability within ±0.025 mm, which is a level of consistency that is virtually impossible to maintain with manual welding.

Cobotics also features a suite of sensors that continuously monitor the torch position, heat input, and seam alignment, then make real-time adjustments if and when needed. With this capability, material waste and scrap rates are reduced, every weld is consistent, and welding defects caused by operator errors and inconsistencies become rare.

With time, precision cobotics don’t just improve quality—they also enhance production efficiency and cost-effectiveness.

Comparing Cobots to Manual TIG Welding

Although cobotics can be extremely precise, manual TIG welding remains an important welding method, especially for tasks that require adaptability and human artistry. But do take note that even skilled and experienced welders experience fatigue and inconsistency during repetitive tasks.

With precision cobots, high-quality welds can be repeatable, which maintains batch quality over long production runs—all without human fatigue and variability. They are also more efficient, especially for high-volume tasks.

You can program a cobot through intuitive drag-and-drop interfaces, which allows even inexperienced operators to track and manage complex weld paths and patterns without comprehensive robotics control experience.

So while human welders are still the gold standard for one-off or highly complex welding jobs, cobots can be better in terms of consistency, speed, and high batch production.

Key Features Enabled by Cobot Manufacturers

Many of the technological advancements in welding cobots come from the innovations of cobot manufacturers. For example, modern cobots today have adaptive control software and integrated sensors to allow the robot to adjust parameters in real time, all to ensure extremely accurate welds under various conditions.

Safety is also paramount, as most cobots today feature collision detection, force-limiting joints, and controlled movement speeds, all to allow themselves to operate safely alongside human welder-operators.

They also feature flexible arm lengths, modular torch mounts, and various payload options to help them handle a wide range of welding applications. With leading cobot manufacturers like Universal Robots and Denaliweld, welding cobotics become much easier to operate, safer, and more efficient.

Advantages and Limitations of Precision Cobotics

Cobots offer several clear-cut benefits: they virtually eliminate the steep learning curve of TIG welding, they can reach challenging positions, and they can operate continuously without fatigue or variability. The result is a higher throughput, decreased error rates, and a highly consistent weld quality.

However, keep in mind that, as robots, they still have limitations to consider. For instance, the initial investment cost for a cobot can be expensive—plus, programming is required when adding and integrating new parts.

Cobots are also known to be less adaptable than humans for complex repair tasks requiring real-time critical thinking and decision-making. But still, for repetitive production tasks, cobots are very compelling.

With a mix of skilled human welders and cobots, you can outsource repetitive tasks to the cobots and let the welder-operators work on the most complex welding jobs

Practical Deployment Tips for Manufacturing

To maximize the benefit of precision cobots, start by thinking about your welding volume and part consistency. If your workflow has a massively high-repetition task pipeline, it can justify the cobot deployment. But if your pipeline has only low-volume or irregular, complex tasks, a cobot’s capability may not be realized in full.

With regards to positioning, always plan workspace layouts carefully since stable fixturing and proper positioning are very important to maintain a consistent weld accuracy. If the robot is not fixed and positioned, a tiny movement can ruin the whole weld.

As for operations, operator training must be done gradually, focusing first on programming, then quality monitoring, and basic troubleshooting—as advanced troubleshooting is reserved for the cobot manufacturer’s technical team. With this step-by-step training, you can gradually build operator confidence without overwhelming them with too much knowledge.

We also suggest conducting regular maintenance, such as torch alignment and environmental control, to maintain consistent system performance and guarantee longevity. By following these practical tips, you can ensure your precision cobotics investment pays off not just in quality, but also financially.

Ongoing Trends: The Increasing Popularity

The use of precision cobots is growing rapidly, driven by technological advances and growing industry needs. This increasing popularity is also fueled by skilled welding labor shortages; however, cobots are not designed to replace human welders—they’re meant to complement.

Modern cobots today are equipped with artificial intelligence and improved software interfaces, making them more adaptable and intuitive than ever. Reprogramming for parts upgrade or replacement is also now faster, making scaling easier and more convenient.

The range of cobotics is also now expanding—with industries like medical, automotive, aerospace, and food technology now using cobots for precision and repeatability-related tasks. With this widening adoption, cobots are now becoming a gold nugget for a practical, scalable modern manufacturing solution.

Conclusion

Precision cobotics are indeed changing the way welding gets done—by combining robotic perfection with human judgment and oversight, cobots can deliver high-quality TIG welds, reduce scrap and waste, and keep your production lines steady even on the longest runs.

Though manual TIG is still needed, especially for customized or highly intricate work, repetitive, and specifications-critical welding is still the cobot’s undisputed specialty.

Ready to see the cobotics difference in your business? Let Denaliweld help you deploy cobots into your production lines. From boosting weld quality to cutting waste and improving production efficiency, our cobot solutions are designed to make your welding operations smarter, faster, and more reliable.

Get in touch with our team today and find out how cobotics can take your production to the next level!