Modern firms have found automation to be integral for boosting the speed, efficiency, and productivity of manufacturing processes. And among advancements in automation technologies, the use of a welding cobot has gained traction across industries.

These programmable robotic machines, with their ability to work alongside human welders, offer top-level precision and consistency to produce repeatable, superior-quality welds in a safe but efficient manner.

In this article, we discuss what cobot welding is and how this technology can elevate your production outcomes and capabilities.

Understanding Cobot Welding

A collaborative robot or “Cobot” is a type of robot that can perform tasks together with human operators. It comes with advanced sensors, an intuitive interface, emergency buttons, and force-limiting features for a safe and effective collaboration with humans.

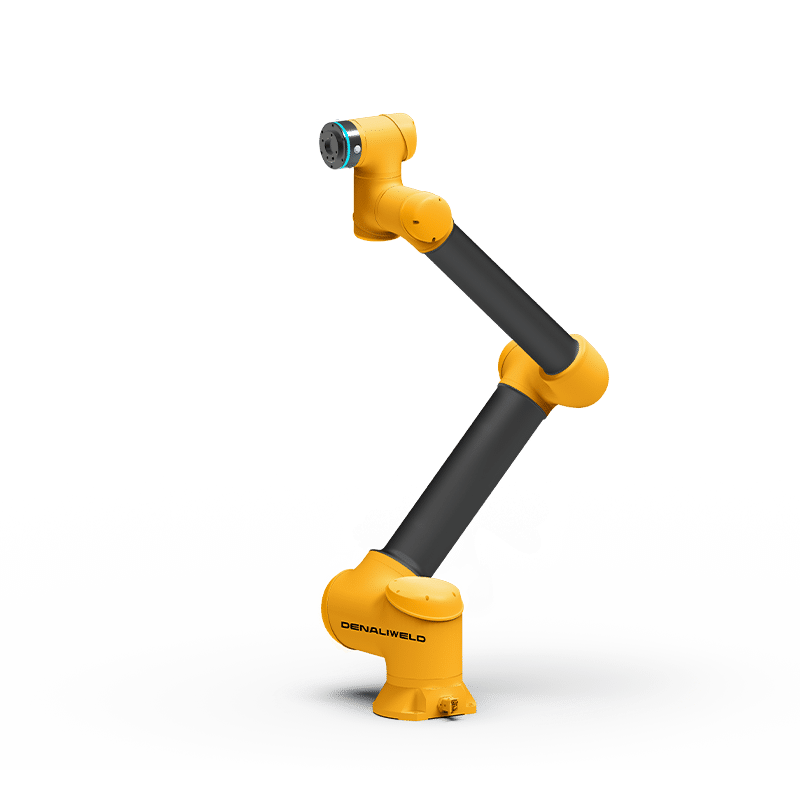

A cobot made for welding projects is called a “cobot welder”. This cobot has a multi-jointed arm (which resembles the human arm) that can move in a wider range. At the end of its robotic arm, there is a welding tool attached. This can be a laser welding head that emits a focused laser or a traditional welding torch.

Unlike traditional welding robots, welding cobots do not require an enclosure or “cage box” as they can operate with human operators safely. Moreover, welding cobots are easier to reprogram and relocate because you can mount (or dismount) them anytime and anywhere. For instance, in the case of changes in operation backlogs or equipment utilization, you may reposition the cobot welders with ease.

Key Trends Driving Cobot Welding Adoption

Several factors pushed cobot welders into prominence, most of which are related to the need to address constraints and the desire for more efficient production solutions.

For instance, many manufacturing firms struggle to hire enough skilled welders for specialized projects. This labor shortage can cause significant backlogs or quality downgrades for the production teams. Hence, companies have started to seek long-term solutions to fill these gaps, and they eventually found cobot welding to be effective in addressing these constraints.

Another factor is the so-called “fourth industrial revolution” (or Industry 4.0), by which automation and data exchange drive modern production processes. Industry 4.0 introduces tools such as data streaming, real-time analytics, and sensors that connect to the Internet of Things. These advancements made it easier (and even cheaper) to adopt and implement cobot welders into the production systems.

The Benefits of Welding Cobots

Listed below are the upsides of integrating cobot welders into your production.

Consistent Weld Quality: With proper configuration and programming, cobots can achieve consistent weld paths with an accuracy of around + 0.0025 millimeters. This means that cobot welders can produce dozens or even hundreds of welds with identical properties. Even a seasoned and skilled human welder cannot achieve this level of consistency.

Increased Productivity: Cobots can work 24/7 without any breaks at a rate that is 30% to 50% faster than human welders. This enables rapid production scaling and reduction of your turnaround times.

Improves Workplace Safety: As cobot welders become part of the welding processes, workers spend less time near hazardous heat, bright light, sparks, and fumes. This reduces the risk of injuries, burns, and respiratory issues. Furthermore, most welding cobots come with advanced sensors that can detect the presence of people and obstacles. These sensors enable the cobot to slow down, stop, or change direction if someone gets too close, which prevents accidents and injuries.

Reduces Production Costs: As cobot welders improve production speed and efficiency, the firm’s overall production capacity increases as well. This is possible even without an increase in personnel costs. In the long term, this enables the firm to produce cheaply and with her higher ROI.

Advanced Technologies: Cobot Laser Welding

In cobot laser welding, the cobot machine uses a highly focused laser to melt and fuse metals. Cobot laser welders are known for their top-level precision as they can operate within ±0.05-millimeter to ±0.1-millimeter weld dimensions. This extreme level of precision ensures low heat input that minimizes thermal distortion to the base materials. As a result, cobots’ laser welds are often clean and durable.

With their superior precision and reliability, cobot laser welders are highly effective for fusing small to medium-sized parts. They also work well with thin and thick materials, as well as those with complex geometries. For these reasons, cobot laser welders are one of the go-to welding solutions of aerospace, automotive, medical, and electronic production industries.

How Denaliweld’s Cobot Solutions Stand Out

Denaliweld is a global manufacturer of industrial laser welding solutions, such as cobot laser welders. Its independently developed cobot welding systems can deliver ultimate precision, efficiency, ease of use, and productivity that meet evolving modern manufacturing standards.

Denaliweld’s Cobots are developed with these features to supercharge an industrial firm’s production capabilities:

- Welding Data Acquisition System: The cobots can automatically monitor and record performance during projects. This simplifies operation tracking activities and improves cost calculations to maximize production returns.

- Seamless Automation Integration: Denaliweld can transition fast from Cobot mode to fully-automated robot mode with a single click.

- Top-Class Automatic Welding Head:An automatic welding head (GCR 5/10/16) supports real-time power adjustments throughout the welding process for improved precision and quality.

- Seam Tracking System: Denaliweld cobots feature an optional seam tracking system that allows for precise weld alignment and improved accuracy.

- Lightweight and Flexible Profile: Weighing only around 22 kilograms to 60 kilograms, Denaliweld’s Cobot series is easy to integrate into various production lines for a versatile solution across industrial applications.

- Industry-leading Speed: Through intensive R&D, Denaliweld came up with an impressive cobot maximum speed of around 3.5 m/s. Now, you can significantly reduce your turnaround times and elevate your ROI.

How to Get Started: Transitioning to Cobot Welding

The first step to cobot welding adoption is to spot a reliable manufacturer of cobot welder solutions. Look for a provider that is compliant with stringent international standards and has an impressive industrial reputation.

For instance, Denaliweld is a cobot laser welding manufacturer with all its machines passing SGS, CE(MD, EMC), WPQR certification, and C Test. This brand serves industries across the United States, Europe, Australia, and Japan, with over 150 dealer stores around the world.

Next is to train your personnel to work alongside cobots. Conduct hands-on training sessions that cover basic operation, troubleshooting, PPE preparation, and safety measures. Hone their cobot skills by training them on working with essential linear and radial weld points using teach pendants or by manually guiding the arm.

Embrace the Future of Industrial Manufacturing With a Welding Cobot

With its superior precision, efficiency, safety, and consistency, cobot welding is a definite step up for your firm’s productivity. Augmenting it to your manufacturing line can speed up your production, reduce overall operating costs, and enhance your output.

For safe and top-quality cobot welding solutions, visit Denaliweld. With over two decades of industry experience, we have served more than 150 US cities with our CE and SGS-certified laser welding machines. We strive to offer 100% reliable, effortless-to-use, and ultra-precise laser welding solutions.