You might have heard that a wide range of industries have already adopted laser welding technologies in their workflow. But what is laser welding used for?

Simply put, laser welding uses a high-energy laser beam to join metals together. The entire process of laser welding is quick and precise. There is minimal heat input, and the heat is concentrated onto a small surface area, leading to reduced risks of deformation compared to traditional welding methods. All of these benefits make it ideal for the controlled precision welding that modern manufacturing demands.

While traditional welding methods, like MIG and TIG welding, provide durable welds with an excellent finish, laser welding is capable of welding tasks that can be beyond the capabilities of traditional welding methods.

Aerospace engineering, automotive manufacturing, electronic equipment, and medical devices are increasingly relying on laser welding to meet stringent safety and performance standards. This article will discuss the applications of laser welding, its main advantages, and what you may need to consider before getting one.

Materials Suitable for Laser Welding

While the laser welding machines can vary in size and power, their versatility and precision allow them to create strong bonds between a wide range of materials. The most common materials subjected to laser welding are materials like stainless steel, aluminum, titanium, copper, brass, and nickel alloys.

While these machines can weld dissimilar metals and composites, they face some challenges. Different metals have different fusion temperatures and conduct heat at different rates. Rather than merging as a homogenous mixture, they’ll join at the interface between the two metals, resulting in a weld that won’t be as structurally strong.

Two strategies are available to address these issues:

The first technique is laser brazing. This process uses a filler material for joining without melting the base material. This filler bridges the differences between the metallurgical properties.

The second technique is laser wobbling. By oscillating the laser beam, the different metals fuse more slowly. However, this process requires additional optical components.

Laser welding can also join ceramics and carbon fiber composites. These materials can prove tricky since the metals need to be arranged so that they physically lock together during welding to guarantee a strong connection. Ceramics need to be preheated before welding, as they can crack when subjected to high heat.

Industrial Applications of Laser Welding

Across a wide range of industries, the demand for durability and precision has made it clear to them what laser welding is used for. Here is how it’s applied across key sectors in manufacturing and production:

Automotive Industry

Engine parts, powertrain components, body panels, and chassis need strong and precise welds. The controlled heat input of laser welding reduces deformation and minimizes the need for any post-weld treatment, saving time and quickening production.

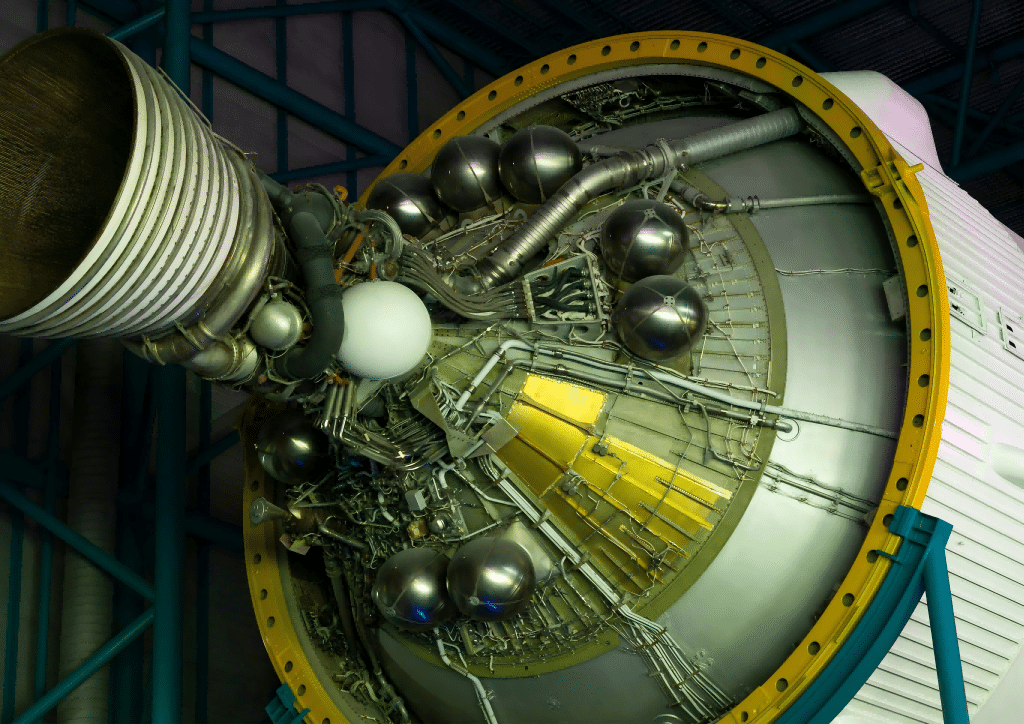

Aerospace Engineering

In the aerospace industry, welds need to maintain structural integrity under extreme conditions. Because laser welding is a low-heat process that can eliminate distortion, its use case is ideal for fuel tanks, turbine blades, and lightweight structural components, especially when ensuring precision and reliability with minimal contamination.

Medical Device Manufacturing

Laser welding can produce the high-quality and precise welds that surgical instruments, medical implants, and diagnostic tools need to meet strict tolerances. Laser welding devices also come with a closed safety shield that can ensure the cleanliness required in the medical industry.

Electronics and Electrical Equipment

The manufacturing of miniaturized components such as circuit boards, battery connections, and microelectronics benefits greatly from laser welding. Laser welding’s ability for precision soldering and minimal heat transfer on more delicate parts ensures the mass production of functional electronic devices.

General Metal Fabrication

Because the laser beam melts materials at the joining place, they can ensure durable and aesthetically pleasing welds. Its versatility can cover larger-scale tasks, such as structural steel parts, to niche applications, such as in metal furniture and custom metal pieces.

Advantages Over Traditional Methods

When compared to traditional welding methods like MIG and TIG, laser welding offers a wide range of benefits.

Because the laser focuses its energy onto a small area, the resulting heat-affected zone (HAZ) is considerably smaller. Only the areas that need to be welded together are heated with less warping or distortion. Since there is no need to compensate for the additional heat, mechanical engineers can opt for thinner materials.

The small, focused beam also allows for higher levels of precision and control. In general, this enables welds with increased strength and stability but also provides flexibility for welding small components, complex shapes, and materials.

Laser welding can also integrate more easily with modern automated and robotic systems. The repeatability and remote capabilities of the technology can help meet demanding production requirements with fewer specialized welders, saving on labor costs and increasing productivity.

Emerging Trends and Technologies

Laser welding technology continues to advance, slowly tearing away previous technical hurdles and expanding what laser welding can be used for. For example, handheld and robotic laser welding products have become more accessible to manufacturers and the general public.

Different laser types have also emerged to meet the needs of different industrial sectors. The most common is the CO2 laser, which utilizes carbon dioxide gas as its active medium. There are also Nd:YAG lasers, which use neodymium-doped yttrium aluminum garnet instead, and fiber lasers that have glass fibers inside.

Improvements to automation and remote welding integrate nicely with laser welding, especially with the promising addition of hybrid laser welding processes that combine laser and traditional welding techniques to ensure high-quality results for more complex materials.

Choosing the Right Laser Welding Solution

While laser welding machines can seem quite versatile, it’s crucial to first understand your specific needs before acquiring one.

Consider the type of material that will be welded, its thickness, production volume, and precision requirement.

Weigh your current situation when it comes to the initial investment versus the long-term cost savings. Laser welding systems tend to be a higher upfront investment. However, they offer lower defect rates, faster processing times, and minimal post-weld treatments, which can translate into significant operational cost savings over time.

Skilled operators still need to be trained on the equipment’s procedures and safety measures. Additional time and training may be needed to ensure a safe working environment and compliance with safety regulations.

Check whether the suppliers would provide warranties and reliable after-sales support. Manufacturers, such as Denaliweld, can ensure fast and professional responses for technical support and training resources.

Conclusion

So, what is laser welding used for?

Laser welding is used to deliver fast, precise, and high-quality welding that minimizes heat impact on the material, which makes it ideal for industries and applications that demand accuracy, durability, and speed. From aerospace to electronics, its versatility and ability to adapt to different materials allowed laser welding to see widespread adoption.

As global industries strive for efficiency and sustainability, laser welding stands out as an inviting solution. Its energy efficiency, lower operational costs, and overall reduced material waste align well with environmental goals and lean production strategies. With continued advancements in laser technology, adoption is expected to rise for sectors seeking cleaner and scalable fabrication methods.

Interested in future-proofing your manufacturing process? Now is the time to explore Denaliweld’s advanced laser welding solutions. Investing in innovative equipment solutions can optimize productivity and weld quality, while also helping you rise above your manufacturing goals.