As the level of science and technology advances, people have higher and higher requirements for welding quality and efficiency. Automated production requirements to reduce labor, improve product consistency, more suitable for mass production, reduce production costs and improve production efficiency. While manual welding, due to the technical level, fatigue, physiological limits and other objective and subjective factors should be affected, it is difficult to maintain the stability and consistency of welding work for a longer period of time. And because of the poor working conditions of welding, people willing to engage in this work is decreasing, the future may face a shortage of skilled technical workers. It can be said that the automation of laser welding is a must. So how do you automate a laser welding machine? What are the advantages of laser welding automation? This article will answer for you.

The working principle of laser welding machine

Laser welding is the use of laser generated high-energy laser beam, through the lens and mirrors and other optical components for focusing, irradiated on the surface of the workpiece so that the temperature rises to a high enough temperature, will make the workpiece melt and form and form a molten pool, as the laser beam moves, the molten pool will follow the movement of the laser beam to stop irradiation of the part of the molten pool will gradually cooled and solidified, so it will be the formation of the next complete weld in the path of the weld, thereby forming a solid weld The next complete weld is formed in its welding path, resulting in a solid weld. Compared to conventional welding technology, laser welding is faster, consumes less power, and is capable of continuous high-speed welding, improving welding efficiency.

Basic requirements for laser welding machine automation

Automation of laser welding machines needs to meet a number of requirements that allow for efficient, accurate and reliable welding operations in a production environment, improving productivity and product quality.

Laser welder automation requires precise positioning and motion control to ensure that the weld head accurately follows the intended weld path and remains stable during the welding process.

Automated welding typically involves a wide range of workpiece types and sizes, so the machine needs to have an adjustable clamping system that can accommodate different shapes and sizes of workpieces and ensure that they are held securely in place during the welding process.

Laser welding machine automation needs to be programmable, with the ability to operate automatically according to pre-set welding paths and parameters.

Automated laser welding machines need to be highly efficient and reliable, able to maintain stable performance over long periods of continuous operation without the need for frequent repairs and maintenance.

Automated laser welding machines need to be easy to integrate and operate, seamlessly connect with other equipment and systems, and be simple and easy to use.

Handheld laser welding machine how to realize automation

The automation of the laser welding machine is of great significance to improve the production efficiency of enterprises, reduce production costs, improve product consistency, etc. Laser welding machines want to realize automation, generally need the following aspects alone or in combination.

Integrating a robot with a laser welding machine allows it to automate welding tasks. The robot can be equipped with grippers and sensors to precisely position the workpiece and move the laser welding head throughout the welding process. This type of system typically uses programmed controls to guide the robot’s movements for complex weld paths and multi-part handling.

A vision guidance system is used to recognize the position and shape of the workpiece so that the welding process can automatically adapt to different workpieces. Such systems typically use cameras and image processing software to monitor the weld area in real time and adjust weld parameters based on pre-set parameters.

Sensors are used to monitor critical parameters of the welding process such as temperature, weld depth and seam quality. These sensors provide real-time feedback to adjust weld parameters and ensure consistent weld quality.

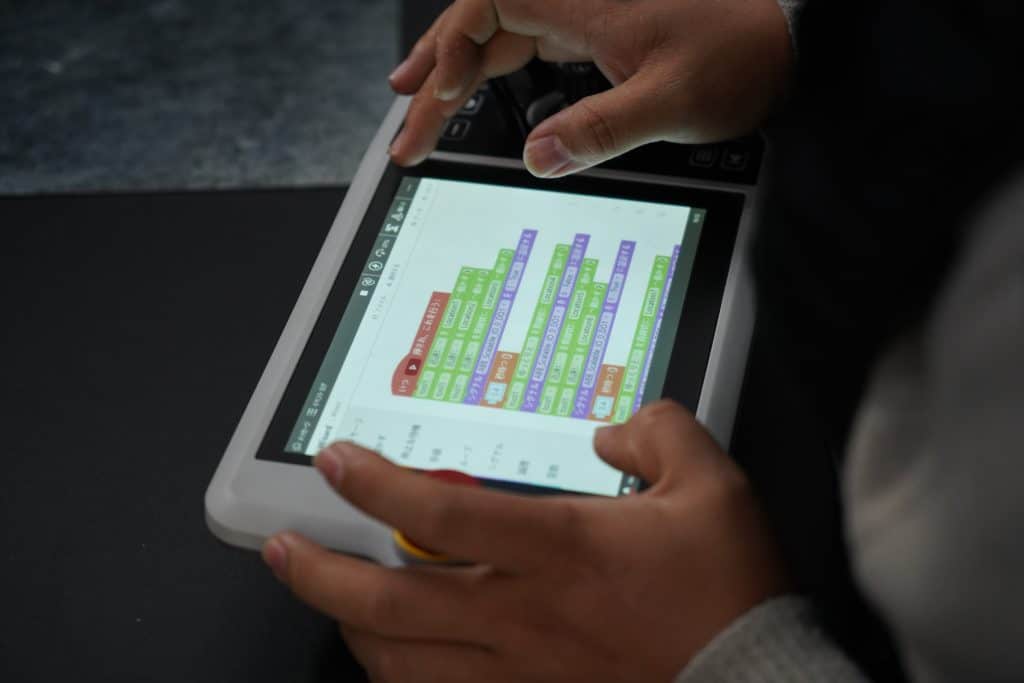

Utilize specially designed automation software and programming to control the operation of your laser welding machine. These software can write complex weld paths and programs to automate the welding process. By pre-programming weld paths and parameters, highly automated production lines can be realized.

Advantages of laser welding robots

In the traditional manual welding, due to the differences in the technical level and experience of the operators, often lead to unstable welding quality, low productivity and other problems, manual welding also exists on the operator’s health hazards. The automation of the laser welding machine is of great significance in improving the welding quality, increasing productivity and safeguarding the health of the operators.

The automatic laser welding machine adopts high-precision laser sensors and control, which can realize the automatic control of the welding process, thus eliminating the influence of the difference of the operator’s technical level and experience on the welding quality. There is no need to contact the processing when working, and no external force is generated on the parts. The heat-affected zone of the laser welding robot is smaller, and the deformation and discoloration of the weld is less, thus ensuring the stability of the welding quality.

Laser welding robot can reduce the labor force of workers, after setting the program, the welding process is completely operated by the robot. The operator of the laser welding machine does not need to be in direct contact with the welding process, which avoids the hazards of harmful gases, dust, etc. produced during the welding process to the operator, thus safeguarding the health of the operator.

Traditional welding in the operation will be subject to the welding environment and human factors, so that the work process slows down, is not conducive to the enterprise rationalization of production. Laser welding robot with high degree of automation, welding speed, can be continuous operation and long time welding tasks, welding efficiency can generally reach several times or even dozens of times the manual welding speed, and, automatic laser welding machine can realize multi-position, multi-angle welding, thus improving the production efficiency.

DENALI laser welding robot adopts human-machine interface, easy and convenient to operate, do not need too much professional knowledge and skills, only need to carry out simple parameter settings to complete the welding task.

Summarize

Through the above analysis, we can see that laser welding robots have many advantages, mainly in terms of precision, efficiency, flexibility and speed. laser welding robots have adapted to the needs of the development of modern manufacturing industry, and provide better welding solutions for various industries. DENALI will continue to research and improve the technology and application of laser welding machines, so as to make it better to serve the society and human beings.