DENALIWELD

Water Cooled Laser Welding Machine

DENALIWELD

Water Cooled 1.5Kw 2Kw 3Kw Fiber Laser Welding Machine

DenaliWeld delivers precision, power, and innovation with our water-cooled fiber laser welding machines. As a proud employee-owned company, we are committed to providing cutting-edge technology and exceptional reliability.

- High Power Output: Supports up to 3000Wof continuous laser output, ensuring consistent and efficient performance across a range of applications.

- Reliable Operation in Extreme Conditions: Designed for continuous use, with reliable performance in environments ranging from -10°C to 40°C (14°F to 104°F).

- Modular Chiller System: Water-cooled with a modular design for easy maintenance and repair, ensuring minimal downtime and optimal cooling.

- Compact & Lightweight: Engineered for portability, it is the smallestand lightest machine in its class without compromising power.

- 3-in-1 Versatility: Combines welding, cleaning, and seam treatment functions in a single machine, providing multi-purpose functionality.

- User-Friendly Controls: Pre-set parametersenable one-click operation, reducing setup time and enhancing ease of use.

- Welding Data Acquisition System: Tracks operation metrics and cost calculations for better process monitoring and efficiency management.

- Automation Ready: Seamlessly switch to cobotor robotic welding with a single click using DENALIWELD ROBOX™, enabling automated precision welding.

Features And Configuration

DenaliWeld Laser Source

Built for precision, power, and reliability, the DenaliWeld Laser Source delivers consistent performance across a range of industrial applications, from robotic to hybrid welding.

- Accurate, Full-Power Output: Provides precise, stable laser delivery, ensuring full power output for superior weld quality.

- Compact & Reliable Design: Designed for continuous operationin demanding environments, with reliable performance from -10°C to 40°C (14°F to 104°F).

- Advanced Laser Control System: Independently designed by DenaliWeld, our system delivers a smooth output curve, resulting in cleaner welds and greater consistency.

- High-Power Capability:

- Up to 8000Woutput for robotic welding, providing speed and precision for automated systems.

- Up to 20000Woutput for hybrid welding, delivering unmatched power for high-performance industrial applications.

Benefit 1: Advanced 976nm Laser Pump Technology

Our laser pump utilizes cutting-edge 976nm technology, achieving an impressive 45% power transfer efficiency—far superior to the less than 20% efficiency of traditional 915nm pumps. Despite its compact size, it delivers higher output power while conserving energy. Although sensitive to temperature, our advanced chiller system ensures the working temperature remains consistently within a safe range, guaranteeing optimal performance and longevity.

Benefit 2: Proundly assembled in the USA

We assemble our equipment locally in the U.S. using top-tier international brand components, adhering to global standards as well as U.S. quality and safety requirements. At the same time, we maintain a robust inventory of parts, accessories, and consumables at our U.S. facility to ensure timely support for maintenance and repair needs.

Benefit 3: Proprietary Laser Control Software

Our independently developed laser control software precisely regulates laser output. By designing a custom output curve, we deliver intelligent and accurate power control, optimizing the welding process for smoother, stronger, and more precise welds.

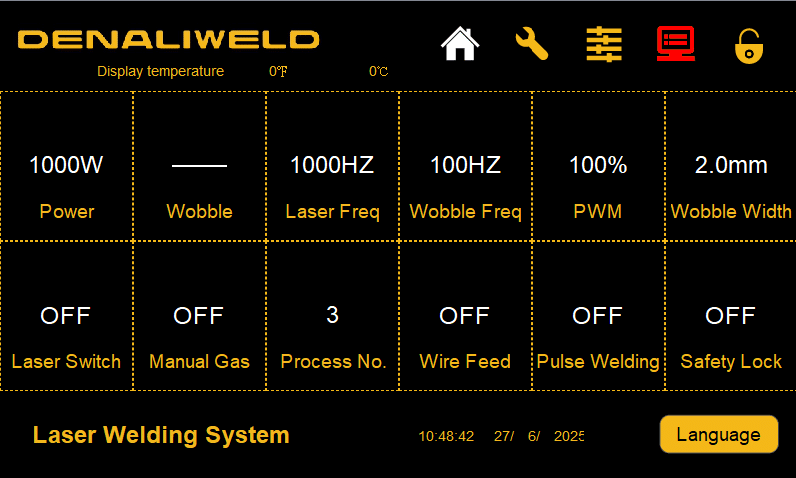

DenaliWeld Welding Control System

- Intuitive Controls: All parameters can be quickly adjusted, allowing for seamless operation and faster setup.

- Flexible Laser Positioning: Effortlessly adjust the laser position without worrying about laser deviation, ensuring precision every time.

- Advanced Safety Features: Built-in safety settingsprovide enhanced protection for both users and observers, ensuring a safer working environment.

- One-Click Welding: Select from accurate preset parameters with a simple click to start welding, improving efficiency and reducing setup time.

Benefit 1: User-Friendly Interface

The intuitive main screen displays all essential information clearly, allowing for easy navigation and quick access to functions. Uploading pre-set parameters is simple, ensuring a streamlined and efficient workflow.

Benefit 2: Comprehensive Access to Settings

Gain full control with easy access to all machine settings. Monitor system status, receive real-time alarm notifications, and adjust the beam center effortlessly to ensure optimal welding precision.

Benefit 3: Advanced Welding Log System

Our Welding Log System records and stores key operational data, including welding time, power, and speed. This data can be saved and uploaded for detailed monitoring, improving quality control and process tracking.

DenaliWeld Laser Welding Head

The DenaliWeld Laser Welding Head is designed for versatility, precision, and operator convenience, offering advanced functionality for demanding industrial applications.

- 3-in-1 Multifunctional Design: Integrates welding, remote cleaning, and seam cleaningcapabilities into a single laser head, enhancing efficiency and operational flexibility.

- Intuitive Status Display: Equipped with indicator lights for real-time monitoring, allowing operators to easily track the machine’s status and performance.

- Advanced water-Cooled System: ensures stable operation for up to four hours without overheating, as verified by test records.

- Ergonomic Design: An ergonomically designed welding machine is available with a physical safety off button, allowing for quick start/stop functionality—even while wearing welding gloves.

Benefit 1

BV certified WPQR of welding. Based on the mentioned advantages above.

Benefit 2

Suitable for both EN-ISO (EU) and AWS (US) standard.

DenaliWeld Water Chiller

Engineered for efficiency, reliability, and sustainability, the DenaliWeld Water Chiller provides superior cooling performance to support long-term laser operation.

- Modular Design for Easy Maintenance: Built with independent modules, allowing for quick maintenance and hassle-free replacement, minimizing downtime.

- Optimized Cooling Efficiency: Designed with precise cooling capacity calculations, delivering maximum cooling performancewhile maintaining minimal power consumption, ensuring stable operation during continuous use.

- Eco-Friendly Refrigerant: Utilizes R410a refrigerant, which complies with environmental standards, ensuring sustainableand responsible

The Key of Cooling

At DenaliWeld, we use an advanced Copper + Aluminum heat exchanging system to provide superior cooling performance. Unlike the micro-tube exchangers commonly found in 99% of coolers on the market, our system delivers much more reliable and efficient cooling, ensuring consistent and optimal temperatures for your laser equipment. This results in longer operational life, enhanced performance, and increased overall efficiency.

DenaliWeld Wire Feeder

Designed for precision and ease of use, the DenaliWeld Wire Feeder seamlessly integrates with your welding system to deliver consistent performance.

- Enhanced Wire Capacity: The newly designed system supports wire feeding up to 2mm (5/64), accommodating a wider range of welding applications.

- Double Wire Feeding: Offers dual-wire feeding capability, increasing efficiency and flexibility for complex welding tasks.

- Seamless Integration: Specifically designed to complement the DenaliWeld laser welding machine, ensuring smooth operation and optimal performance.

- User-Friendly Operation: Equipped with a physical control buttonfor easy operation, even while wearing welding gloves—ensuring quick adjustments and enhanced convenience.

Technical Parameters

| Laser Power | 1500W | 2000W | 3000W |

| Operating System | 3-in-1 / Cleaning | 3-in-1 / Cleaning | 3-in-1 / Cleaning |

| Laser Wavelength | 1060-1100 nm | 1060-1100 nm | 1060-1100 nm |

| Fiber Length | Approx. 10 m (32.8 ft) | Approx. 10 m (32.8 ft) | Approx. 10 m (32.8 ft) |

| Operating Mode | Continuous/Modulated | Continuous/Modulated | Continuous/Modulated |

| Oscillation Operation Mode | Spot, Line | Spot, Line | Spot, Line |

| Positioning | Laser red dot | Laser red dot | Laser red dot |

| Gas flow rate | 10-15L/min | 10-15L/min | 10-15L/min |

| Voltage | AC220V/380V±5% | AC220V/380V±5% | AC380V±5% |

| Power Consumption | 7kW | 9kW | 11kW |

| Frequency | 50/60 Hz | 50/60 Hz | 50/60 Hz |

| Current | 32A/19A | 40A/24A | 29A |

| Focus Length | 150mm | 150mm | 150mm |

| Welding Speed | 0-95cm/min (0-37.4 in/min) | 0-105cm/min (0-41.3 in/min) | 0-105cm/min (0-41.3 in/min) |

| Cooling System | Water cooling | ||

| Laser Protecion Method | laser beam lock + security lock + safety button | ||

| Touch Panel | Monitor + PLC | ||

| Wire Feeder | Single/Double Motor Automatic | Single/Double Motor Automatic | Single/Double Motor Automatic |

| Wire Diameter in Automatic Mode | 0.8 mm, 1.0 mm, 1.2 mm, 1.6 mm, 2.0 mm (0.030", 0.035", 0.045", 1/16", 5/64") | ||

| Machine Weight | Approx. 80kg/176bl | Approx. 85kg/187bl | Approx. 90kg/198bl |

| Machine Measurements | Height 810mm, Width 580mm, Length 1170mm | Height 794mm, Width 497mm, Length 984mm | Height 1000mm, Width 720mm, Length 1370mm |

| 3-in-1 Laser Head Weight | Approx. 900g/1.98lb | ||

| 3-in-1 Laser Head Size | L: 273.38mm, W: 36.5mm, H: 168.57mm | ||

| remark: | cleaning function Max. 2kw for opertion |

Why Choose Us.

DenaliWeld Advantage

Our Services.

We Provide Best Services

Laser Equipment Manufacturer

DenaliWeld, a globally recognized laser equipment manufacturer, harnesses cutting-edge proprietary technology to dominate the laser welding industry, consistently delivering unmatched precision and groundbreaking innovation to our worldwide client.

Local Services

Based in Illinois with 4 global offices, our local teams ensure fast response and professional 24/7 service after your purchase with fair laser welder cost.

Certification

Machine passed SGS,CE(MD,EMC),WPQR certification &c test.

Research and Development

With our exceptional R&D capabilities, we stand among the few companies designing and manufacturing in-house laser sources, control systems, coolers, and setups, delivering precision, reliability, & tailored laser weld solutions for various industries.

Explore More

Global Services

DENALIWELD has four branches and more than 150+ dealer stores around the world. The branches can provide warehouses, inventory machines, spare parts, services, training and showrooms in local and neighboring countries.

USA

2531 Technology dr 310 Elgin IL 60124

Europe

Hantverksgatan 3 S-533 33 Gotene

Australia

1310 Boundary Road Wacol QLD 4076

Japan

中町3丁目10-11 小田原市, 神奈川県

FAQ

What Is The Warranty For DenaliWeld Machines?

We will provide a 2-year warranty on the entire DenaliWeld machine, during which the customer will receive full and prompt service. In case of non-human damage, DenaliWeld will send spare parts free of charge to replace any damaged part on the machine.

Can I Get DenaliWeld’s Services Overseas?

DenaliWeld can provide overseas service including installation, commissioning, training and maintenance to customers all over the world.

How Can I Become One Of The DenaliWeld Agents In My Country?

A detailed answer to provide information about your business, build trust with potential clients, and help convince the visitor that you are a good fit for them.

How do I contact the DenaliWeld dealer in my local city?

If you would like to contact your local DenaliWeld agent, you can send an email to [email protected], or submit a form and we will ask them to contact you directly. You can also check whether there is a local dealer through our dealer locator. We usually indicate the dealer’s contact information.

What is the shipping method for DenaliWeld machines?

If a customer orders a small machine with wooden packaging, we will deliver the machine in a consolidated container, or if the customer orders two or more machines together, we will ship them in a container and send it to the port, which will help the customer save even more money.

What about the quality of DenaliWeld machines?

We have a world-class R&D team to support the quality of our machines, and our products are CE and SGS certified, proving the advantages of DenaliWeld machines.

CONTACT US

INTERESTED IN DISCUSSING?

Customize a solution to your needs today Experience a live demo and get free samples