With the continuous upgrading of laser welding technology, laser welding technology has taken a qualitative leap. It is now maturely used in many fields such as high-tech electronics, automobile manufacturing, precision machining and so on. As a direction of laser application, laser welding is a combination of modern technology and traditional technology. Compared with traditional welding, laser welding has certain incomparable advantages and covers a much wider field than traditional welding methods.

Advantages of laser welding machines

Laser welding machine adopts laser beam for welding, laser has the characteristics of high energy density and strong focusing, which can provide enough heat to realize rapid welding in a short time, and the welding speed is usually 5-10 times faster than the traditional welding method. At the same time, the laser beam is easy to control the characteristics of the welding work more convenient automation and intelligence, with the robot, you can automatically control the welding process, improve production efficiency.

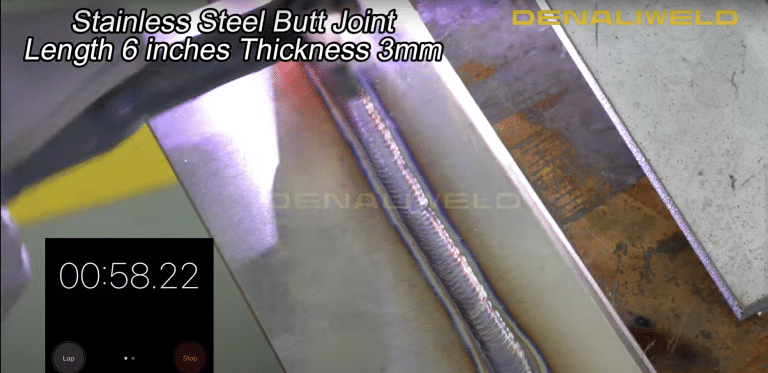

Laser welding is about 4 times faster than Tig welding for the same 3mm thickness, 6” length of stainless steel plate.。

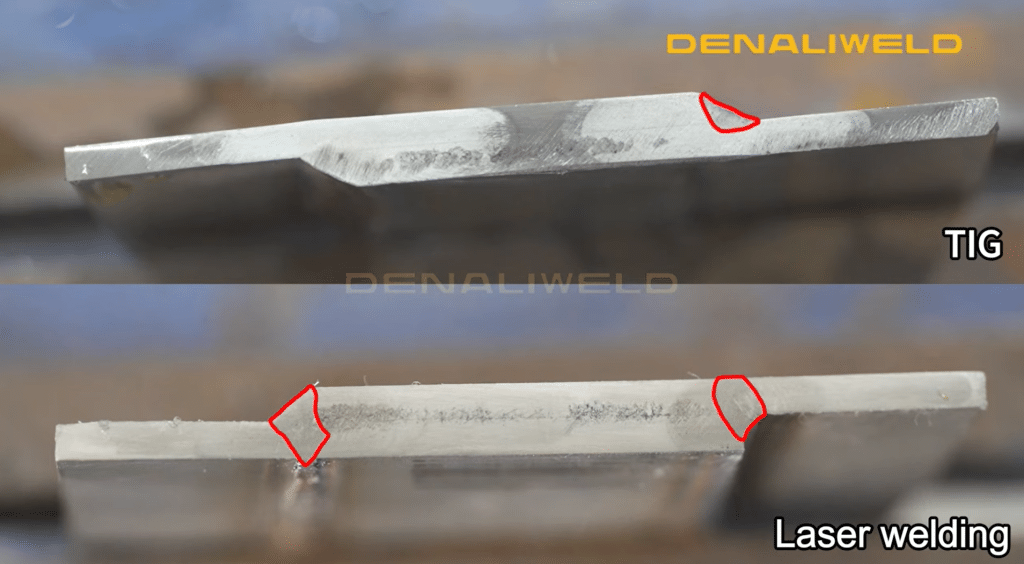

Laser welding machine welding process without mechanical contact, the welding area is less affected by heat, not easy to deformation, blackening and other issues; weld seam beautiful and flat, more in line with modern high-quality requirements; weld solid, comparable to the parent material, the inspection of the welded workpiece will not break from the weld.

Laser welding speed is relatively fast, which is conducive to reducing the oxidation reaction, the plate after welding usually does not need to be ground and polished, which can greatly reduce the cost of late welding, and at the same time solved the use of traditional welding machine when the weld through the weld, weld aneurysm and other problems.

In our practical tests, laser welding is significantly ahead of tig welding (without beveling) in terms of depth of weld and welding speed.

A video can be seen in the tig welding transverse heat affected zone is very large, giving a person in the intuitive feeling of the depth of fusion is very high, but in the cutting weld etching will find that the tig welding depth of fusion can only reach about one-third of the laser welding!

Argon arc welding, for example, argon arc welding needs to have months or even 3-4 years of experience above the welder, handheld laser welding even if there is no welding experience, in the hands of 30 minutes or so can be welded out of the excellent weld, and argon arc welding generally need to be polished after the welding process, and handheld laser welding almost no need to be polished, or only need to be slightly polished, and also saves some of the cost of polishing. Currently the life of the laser has reached 10,000 hours or so, if you pay attention to routine maintenance, reduce the machine failure rate, you can use a longer time.

The laser welding machine can be used for welding carbon steel, stainless steel, alloy steel, iron, aluminum and its alloys, titanium alloy, copper and other materials. In addition to common metals, the laser welding machine can also weld some metal materials with special properties, as well as ceramics, plastics, plexiglass and other types of materials, which have wide applicability in different industries and applications. The current advanced laser welding machine is equipped with a three-in-one multifunctional laser head with three functions of welding, weld cleaning and remote cleaning, which can meet a variety of user needs.

It can weld not only precision parts, but also large and shaped workpieces to meet different welding needs. The laser beam is easy to focus, align and direct by means of optical instruments, can be placed at a suitable distance from the workpiece, and can be redirected around the workpiece or between obstacles in the machine, which other welding methods are not able to perform due to the space constraints mentioned above. Welding can be performed at room temperature or under special conditions, such as when the laser passes through an electromagnetic field without deflection of the beam; the laser can weld in vacuum, air, and in certain gaseous environments, and can weld glass or transparent materials with the beam.

Traditional welding generally produces a large amount of welding dust and slag, which is harmful to the operator and the environment, while laser handheld welding produces less fumes and dust, which is relatively less hazardous to the operator’s health.

Laser Welding Machines Disadvantages

Laser welding has its drawbacks, and before investing in this technology, it is also important to recognize these drawbacks associated with laser welding, which will help you better understand the choice of whether or not to purchase a laser welding machine.

Laser equipment and its associated systems are costly. The upfront purchase price of a laser welding system can be several times that of a conventional welding system, making the one-time investment relatively large. Due to the high cost, laser welding may not be suitable for certain applications for small businesses or manufacturers on a tight budget. However, there are certain areas and applications where the potential advantages and benefits of laser welding may outweigh the upfront costs.

Laser welding has a more limited depth of fusion capability than conventional welding. Some thicker materials require a high depth of fusion welding, which may not be possible with a laser welder. Understand the specific requirements of the welding job before starting the welding job, evaluate and use the more appropriate welding method for the job.

Laser welding machines are not suitable for all types of metals. For example, highly reflective metals such as aluminum and copper alloys reflect part of the laser beam, which prevents the laser from concentrating heat, resulting in poor welding results.

The laser welding machine produces very concentrated energy during welding, which may cause eye discomfort, pain or even vision loss if not taken or improperly protected. In addition, the welding process may also produce exhaust gases or particles that may be harmful or toxic if inhaled.

It is therefore important to take appropriate safety measures, such as wearing goggles, using proper ventilation systems and following safety procedures. Failure to address these safety issues can lead to accidents, injuries and long-term health problems.

Limited Joint Access can have a significant impact on laser welding. Since the laser beam can only reach a specific part of the joint, the size and shape of the part to be welded must be carefully considered. This means that welding parts with complex geometries or difficult-to-access locations can present challenges. Achieving full weld penetration may require multiple welds or part repositioning, which can further complicate and lengthen the welding process. Essentially, limited access to the joint can hinder the simplicity and efficiency of laser welding, so it is necessary to overcome and overcome these potential obstacles to ensure a successful weld!

Laser welding is a new high-tech welding technology that provides manufacturers with efficient welding solutions. Although there are some limitations to the technology, these can be overcome with a little care. If you are in the metal fabrication industry and are looking for an efficient and precise welding solution, then a DENALI laser welding machine may be just what you need!

Learn more about what to look for in a laser welding machine.