In the modern manufacturing industry, laser welding technology has become a commonly used welding method. The power of the laser welding machine is to determine the welding quality of one of the important factors, how to adjust and control the power of the laser welding machine, become one of the key factors affecting the welding quality. In this paper, we will discuss the impact of laser welding machine power on welding quality.

The principle and process of laser welding

Laser welding is the use of high-energy laser beam generated by the laser, through the lens and mirrors and other optical components for focusing, irradiation on the surface of the workpiece so that the temperature rises to a high enough temperature, will make the workpiece melting and the formation of the formation of a molten pool, with the movement of the laser beam, the molten pool will follow the movement of the laser beam to stop irradiation of the part of the molten pool will be rapidly cooled and solidified, the formation of the next complete weld in the path of the next complete weld The next complete weld is formed in its welding path, a welding method that creates a solid weld. Compared with traditional welding technology, laser welding is fast, low power consumption, can realize continuous high-speed welding, improve welding efficiency. Welding power is the key parameter to control the welding effect, which is an indispensable factor in the laser welding process.

The influence of welding power on welding quality

Laser welding power is one of the important factors affecting welding quality. To do a good job of laser welding process control, it is necessary to make a reasonable choice and adjustment of welding power. In the actual welding process, according to the physical and chemical properties of the material, the thickness and shape of the weldment and other factors to consider, select the appropriate welding power, so as to ensure good welding results.

The size of the welding power affects the depth and width of the weld. When the power increases, the depth and width of the melt will also increase, the power is too high may cause the workpiece welded through, deformation and other problems; power reduction, the depth and width of the melt will be reduced, the power is too low, it is difficult to realize the deep or wide weld.

The amount of welding power also affects the appearance and shape of the weld. Too much power will lead to obvious bulges after solidification of the weld, and too little power may lead to cracks, holes, irregular shape of the weld and other problems, affecting the appearance of the weld.

The size of the welding power has a decisive influence on the strength and toughness of the weld. Welding power is too low may lead to inadequate welding, welding depth is not enough, the strength of the weld is low; welding power is too high will make the weld depth is too deep, and easy to form color difference in the welding process, weld holes and other defects, the appropriate power can be obtained good welding quality.

Other factors affecting weld quality

Welding speed will directly affect the quality and efficiency of welding. Welding speed is too fast will appear the workpiece can not melt through, the weld strength is weak, etc., welding speed is too slow will appear the depth of fusion is too deep, deformation of the workpiece and other problems, so in the use of laser welding machine work, according to the material of the welded workpiece, the thickness of the welding thickness of the appropriate adjustments will be a greater enhancement of production efficiency.

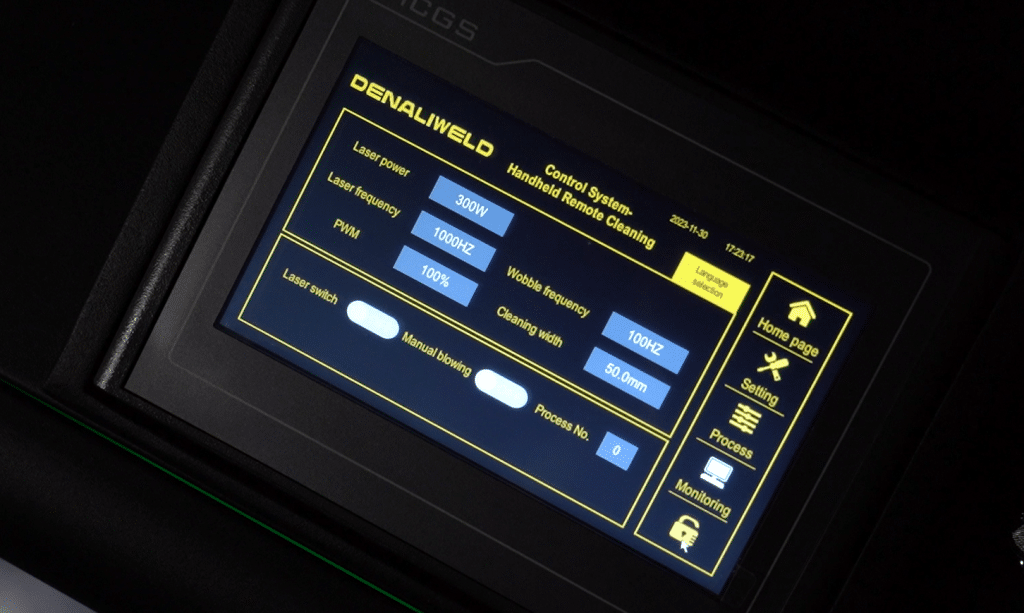

The focusing effect of the laser beam and the position of the focal point is also an important factor, if the focusing effect is poor or the position of the focal point is shifted, it will affect the formation of the weld seam and the quality of the weld.DenaliWeld’s self-designed laser control system, the output curve is smooth, the welding is smoother, Denali all laser welding machines have CE, FDA and SGS certificates.

The welding thickness of any welding machine is limited, as the thickness of the workpiece increases the power of the laser welding machine has to increase, and finally reach the maximum limit.

How to choose the welding power

Generally speaking the higher the power of the laser welding machine the higher the price will be, and the thickness of the material that can be welded is also thicker, when choosing a laser welding machine, you need to consider the following reasons:

Different materials require different welding power. Generally speaking, metal materials require higher welding power than non-metallic materials, highly reflective metals such as aluminum alloys, etc. than low-reflective metals such as carbon steel require higher welding power, according to the workpiece material to choose or adjust the welding power.

Select the welding power according to the requirements of the weld. If you need a high strength, high quality weld, it is recommended to choose a higher power laser welding machine; on the other hand, if you only need to carry out a simple weld, the strength and toughness of the requirements are not too high, you can choose a lower power of the laser welding machine.

According to the needs of production efficiency to choose the welding machine power. As the laser welding power increases, the welding speed will be correspondingly faster, if you need to carry out high-efficiency production, you can choose a high-power laser welding machine; if the production efficiency is not high, you can choose the power of the moderate laser welding machine.

It should be noted that if you are not sure of the above conditions of use, it is recommended to purchase a high power laser welding machine, because modern laser welding machine power is generally adjustable, buy a higher rated power laser welding machine in a low power welding needs can be adjusted down the power to meet the needs of a variety of needs, but a low rated power laser welding machine can not be adjusted to a higher level, unable to meet the needs of the high power welding.

Summarize

Choosing the right power of the laser welding machine is the key to ensure welding quality and productivity. In the actual welding process, the suitable welding power should be selected according to a number of factors such as the material, thickness and shape of the workpiece, so as to ensure good welding results.