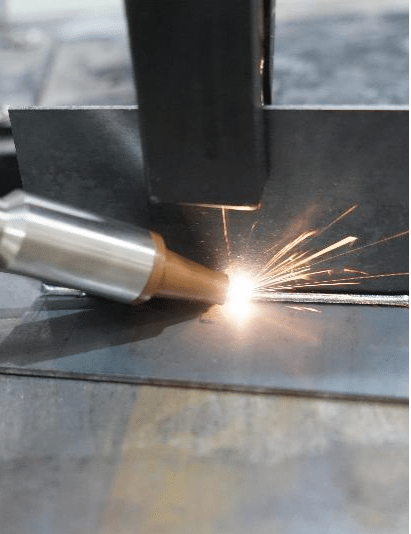

Handheld laser welding machines are popular for thin plate welding. They offer high quality, efficiency, and beautiful welds. Choosing the right model is crucial for optimal use.

The cooling system is essential for the laser welding machine. It prevents overheating, ensures equipment runs smoothly, and protects accessories from damage. We have received customer questions about choosing between water-cooled and air-cooled handheld laser welding machines. In this discussion, we will briefly explain how to decide which cooling method is best for your needs.

Air-cooled laser welding machine

An air-cooled laser welder is a type of laser that uses air cooling to stay cool. This is usually done with a built-in fan. The fan helps to prevent the laser from overheating during use.

The body is small and easy to move. It can be placed in the trunk of a car and is cheaper.

Water-cooled laser welding machine

Water-cooled laser welder is widely used in the market. The laser is cooled by water circulation, and the setting is regulated by the temperature controller. Low noise and easy maintenance cost.

Air-cooled and water-cooled differences

Air-cooled handheld laser welding machine is very small in size and weight because there is no water tank, and the weight is basically 30-40 kilograms. The volume is also basically half the size of water-cooled handheld laser welders. Therefore, in terms of mobility, air-cooled handheld laser welding machine has a very big advantage indeed!

The water cooler is a separate device, so the device takes up more space, high-power laser equipment water-cooled volume and weight is usually more than double the air-cooled equipment.

The cooling effect of water cooling is better than that of air cooling. In the past, air-cooled laser welders had shorter operating times. They needed to stop for a few minutes after running continuously for a while.

DenaliWeld CUAL™ mosaic laser source can run for a long time like water-cooled sources. It can work well in temperatures from -20 to 55 degrees Celsius.

Water-cooled laser welding is typically available 24 hours a day.

Both water-cooled and air-cooled cooling equipment require regular maintenance during use. Regularly replace the water in the water tank to ensure that the water is pure. Distilled or purified water is recommended. There should be no debris in the cooling water, and pay attention to whether the water in the return pipe flows smoothly.

Whether it is water-cooled or air-cooled system, the water tank or fan should be free of dirt and should be cleaned regularly.

The laser welding machine also needs to pay attention to the following points during operation:

1, if the water tank is not running or there is no water, please do not use and exclude the semiconductor laser welding machine. Because the semiconductor laser welding belongs to high temperature thermal processing, if not water cooling will cause serious consequences.

2、Please turn off the power in time if there is any abnormality during operation. After the vibrating mirror stops working, some inspection and maintenance work should be carried out.

The last

We must follow the manufacturer’s instructions when using a water-cooled or air-cooled laser welding machine. The welding quality and the stability of the equipment work are directly related to this.

Learn more about what to look for in a laser welding machine.