With the progress of science and technology and the improvement of the quality of life, people’s requirements for cleanliness and precision are getting higher and higher, and it is difficult for traditional cleaning methods to meet the growing demand. Laser cleaning technology, as one of the important applications of laser technology, has become a powerful tool for solving cleaning problems. Laser cleaning machines have been widely used in many fields with their high efficiency, convenience, precision and environmental protection, etc. Its future development trend will be more extensive, efficient and intelligent in many aspects.

Laser cleaner working principle

According to the different lasers, laser cleaners are divided into two types: continuous laser cleaners and pulsed laser cleaners, and in the field of laser cleaning, pulsed lasers have a much wider range of applications than continuous lasers. For the specific difference, please refer to <How to choose between continuous laser cleaner and pulsed laser cleaner>.

Continuous laser cleaning machine will be a high-energy laser beam irradiation to the surface of the workpiece, the laser energy absorbed into the surface of the organic and inorganic impurities, these impurities absorbed by the laser energy will be heated to a transient high-temperature state, so that the evaporation or vaporization of the phenomenon will be the use of the phenomenon of the surface of the removal of impurities.

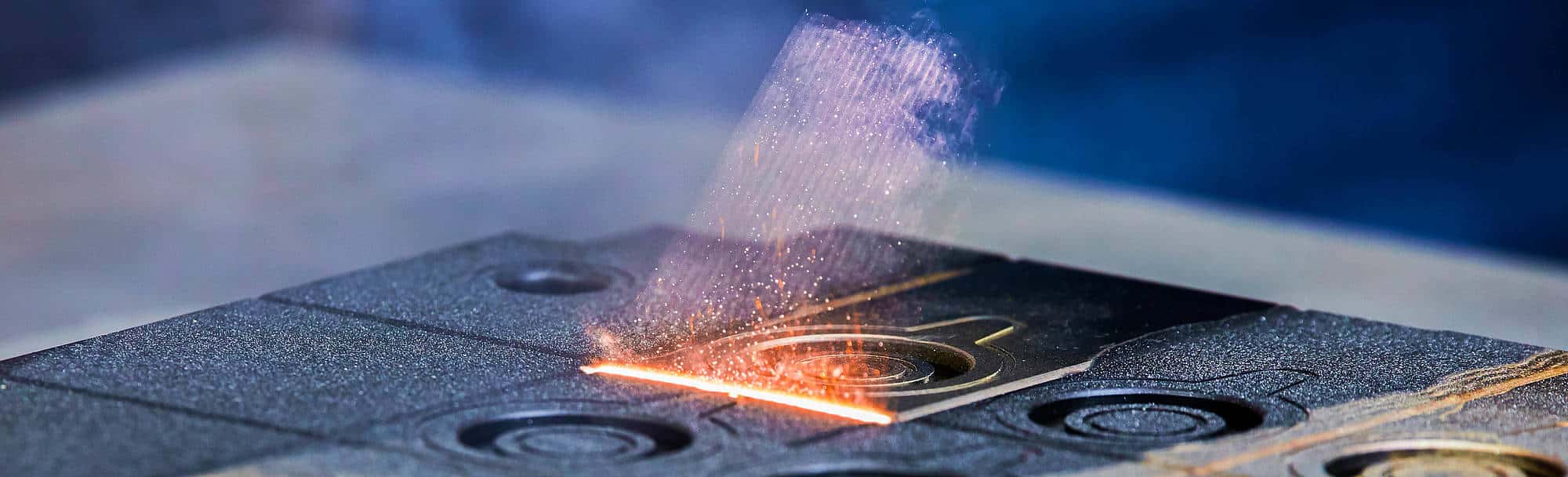

Pulsed laser cleaner outputs the laser beam in the form of pulses, each pulse has higher energy and high instantaneous power, through the high energy of the laser pulse instantaneous irradiation, the surface dirt of the workpiece will be expanded from the surface at a very fast speed and reach more than twice its capacity, becoming easier to peel off, this process is called instantaneous expansion and easy to dissociate, and at the same time, it will produce a laser striking effect, which will turn this dirt into fragments and is removed.

Advantages of laser cleaning

Laser cleaning technology is a new technology that utilizes the interaction effect between the laser and the material, and has obvious advantages compared with the traditional mechanical cleaning method, chemical corrosion cleaning, liquid-solid powerful impact cleaning, high-frequency ultrasonic cleaning and other traditional cleaning methods.

Laser welding machine work process, do not need to use any cleaning fluid or other chemical solutions, will not cause corrosion of the surface of the workpiece.

Most of the traditional cleaning methods are contact cleaning, the surface of the workpiece has a mechanical force, easy to cause damage to the surface of the workpiece, laser cleaning non-abrasive and non-contact characteristics, so that it avoids the emergence of this problem.

Laser cleaning does not have the tedious steps of traditional cleaning methods, fast cleaning speed and high efficiency.

The laser welding machine only consumes electricity during the use process, and the long-term stable use of the operating cost is low.

Laser cleaning machine by adjusting the parameters, can remove various types of pollutants on the surface of various materials, without damaging the surface of the workpiece under the premise of achieving the effect of conventional cleaning methods can not be achieved to meet the production needs of various industries.

Laser Cleaners in Manufacturing

The many advantages of laser cleaning have led to its widespread use in industrial manufacturing.

The electronics industry on the precision and cleanliness requirements are extremely high, in the circuit board before welding, component pins must be thoroughly removed oxides to ensure the effect of electrical contact, and in the decontamination process can not damage the pins, laser cleaning can meet this requirement.

Before the soldering work, the workpiece is de-rusted, de-greased and oxides are removed after soldering.

For example, after an airplane has been in flight for a period of time, it is necessary to remove the old paint on the surface and repaint it. Traditional paint removal methods are prone to damage the surface of the airplane, which may pose a safety hazard to the airplane, but laser cleaning will not cause such a situation.

Laser cleaning machine can be used to clean automobile parts, such as engine, brake system, chassis, etc., to remove the surface oil, carbon, rust, etc., to improve the surface quality and durability of parts.

Laser cleaning machines can be used to clean building materials such as building facades, glass curtain walls, stone, etc. to remove surface dirt and pollutants and improve the aesthetics and service life of the building.

For example, removing stains such as grease, resin, glue and dust.

Laser cleaning in heritage conservation

Pulsed laser cleaners have become an important tool in the field of heritage conservation due to their high efficiency, non-contact and precise cleaning characteristics. The main applications include building restoration, stone, metal and wood cleaning, sculpture cleaning, cleaning of antique cars, antique boats, antique machinery, graffiti cleaning, lead-based paint removal, art conservation, painting conservation, paper conservation, wood conservation, leather cleaning, conservation of artifacts, archeology cleaning etc.

Future Trends of Laser Cleaners

As a state-of-the-art cleaning technology, laser cleaners show strong potential for continuous innovation and development. Its future trends will be characterized in many ways by greater breadth, efficiency and intelligence.

With the development of the economy and the optimization and upgrading of industrial structure, especially in the field of electronics, optics, chemistry, biology, etc., the demand for laser cleaning technology will continue to increase. In addition, the progress of science and technology will also promote the application of laser cleaning technology continues to expand, such as in the semiconductor, solar cells, optical fiber and other fields.

Laser cleaning machine will continue to carry out technological innovation, improve the cleaning effect and efficiency, while reducing costs. For example, the power of the laser cleaning machine may be further improved, making the cleaning speed faster; or the precision and stability of the laser cleaning machine may be further improved, making the cleaning effect better.

With the development of artificial intelligence technology, the laser cleaning machine may be more intelligent, automated control and intelligent fault diagnosis. For example, the laser cleaning machine may be equipped with intelligent sensors and control systems to realize automatic identification, positioning and cleaning.

The application areas of laser cleaners may be further expanded, for example, in aerospace, automotive manufacturing, construction and other fields. In addition, laser cleaners may also be used in emerging fields such as biomedical and food processing.

Summary

Laser cleaners have several advantages in modern industry, including improving product quality, reducing costs, increasing productivity and safety, etc. With the continuous progress of technology and the expansion of application fields, laser cleaners will play their advantages in more fields and provide important support for the development of modern industry.