Laser welding machine is a high-tech product that is widely used in the manufacturing industry due to its high precision and efficiency. However, the huge prices of different models and configurations of laser welding machines make price one of the key considerations when purchasing a laser welding machine. What factors lead to the price difference between these laser welding machines? How should we choose a cost-effective laser welding machine? This article will detail the price range and market conditions for laser welding machines, as well as important considerations when evaluating the cost of a laser welding machine, and choosing the right laser equipment for your needs according to actual requirements.

Components of a laser welding machine

Laser Source

The laser is the core component of the laser welding machine, and its main function is to generate a laser beam as a heat source for the welding process. The laser beam produced by the laser is characterized by high energy density, high precision and high directionality, and can be focused to a very small area to achieve welding.

Power source

The role of the power supply is to convert the AC power supply to DC power supply, to provide stable current and voltage for the laser, to ensure the stability of the laser’s output power and wavelength, but also play a role in controlling the laser switch.

Control system

The control system can adjust the laser power, frequency, focal length, spot size and position, etc., to ensure the safe and reliable operation of the whole machine and improve the welding quality.

Cooling System

Welding process laser and welding head will produce a lot of heat, the role of the cooling system is to discharge the heat to ensure the stable operation of the equipment. Cooling system is divided into water-cooled, air-cooled, of which water-cooled system is more common.

Welding head

The welding head, also known as the welding torch, is a device that transmits the laser beam to the workpiece, which consists of a refracting mirror and a focusing mirror. The welding head can focus the laser beam as needed to produce a laser welded spot with high energy density.

Price Range of Laser Welding Machines

With the widespread use of laser welding technology, more and more consumers are considering laser welding equipment. Price is a major concern for consumers, so here is an analysis of the price range of laser welding machines.

Entry-level compact laser welding machines

Entry-level laser welding machines are a great option for small businesses or individuals who are just getting started with laser welding technology. They are relatively inexpensive, usually ranging from $5,000 to $10,000. However, due to their lower laser power, they are better suited for small batches and low-demand welding tasks and may not perform well in large-scale or demanding industrial applications.

Mid-Range Laser Welders

Mid-range laser welding machines offer a higher level of performance and functionality for specific industrial applications in medium-sized businesses. These machines typically feature moderate to high laser power, more precise welding results, and more configuration options. They are typically priced between $10,000 and $30,000, but may vary depending on factors such as technical parameters, manufacturer, optics and control systems. Mid-range laser welding machines are suitable for medium-sized production and more demanding welding tasks, and can provide efficient, high-precision weld results.

Industrial and high-end laser welding machines

Industrial and high-end laser welding machines are the most advanced and powerful machines on the market, designed for large-scale industrial manufacturing and demanding applications. These machines feature the highest laser power, state-of-the-art optics, sophisticated control systems and a wide range of configuration options. They are capable of handling a wide range of complex welding tasks, including large workpieces, high-speed production and precision requirements. Prices typically range from $30,000 and up, depending on model and customization options. These high-end machines are usually produced by large industrial manufacturers and come with full after-sales service and maintenance support.

Choosing the right machine can lead to better productivity and weld quality for your organization. It is important to note that these prices are for reference only, and actual prices may vary depending on market demand, technological innovations and supplier strategies. When choosing a laser welding machine, don’t consider the price alone, you should carefully consider various factors according to your industry and needs, and compare with multiple suppliers to ensure that you choose the most suitable equipment for you.

Factors affecting the price of laser welding machine

There are more factors affecting the laser welding machine, which can be roughly divided into the following aspects;

Laser source technology and power

The price of a laser welding machine is mostly determined by the power and technology of the laser source. The kind and power of the laser source have a major impact on the functionality and efficiency of a laser welding machine. Different types of laser generators, such as fiber lasers, CO2 lasers and solid-state lasers, have their own advantages and scope of application. Fiber lasers have the advantages of high energy density, long life and low maintenance cost, and are usually suitable for precision welding and high-efficiency processing. CO2 lasers and solid-state lasers, on the other hand, are suitable for welding tasks with different materials and thicknesses.

When choosing a laser welding machine, you need to select the right type of laser source and power level according to your actual needs and budget. Higher power laser welding machines are usually more expensive, but enable faster and more efficient welding. For large workpieces or high-speed production needs, high-power equipment is necessary, but low-power equipment may be sufficient for small workpieces or precision welding at a relatively low price.

Equipment Configuration

The size of the weld area and equipment configuration, in addition to the technology and power of the laser source, will also have an impact on the cost of a laser welding machine. Different sizes and models of laser welding machines have different welding areas and configurations to meet the needs of different applications. Machines with large work areas and flexible machine configurations are usually priced higher because they are able to handle larger and more complex workpieces. Furthermore, the cost of equipment with sophisticated features like beam delivery systems, motion control systems, and real-time monitoring is higher.

These advanced features can improve welding accuracy, stability and reliability, and reduce manual intervention and labor costs, but they are not required, so you need to balance the performance of your equipment with your budget based on your actual needs when choosing a laser welding machine. Some basic configurations and features are sufficient for many people’s welding needs and are more affordable.

Manufacturing and Branding

For those on a budget, take into consideration selecting from a number of competitive small to medium-sized manufacturers or emerging brands. These manufacturers may be able to offer more competitive pricing, as well as a certain level of assurance in terms of equipment performance and after-sales service. However, it is still necessary to carefully assess the specific features, performance, and reliability of the equipment when making a selection to avoid potential problems. Well-known brands typically have higher market recognition and reputation, and these brands usually focus on the quality and performance of the equipment.

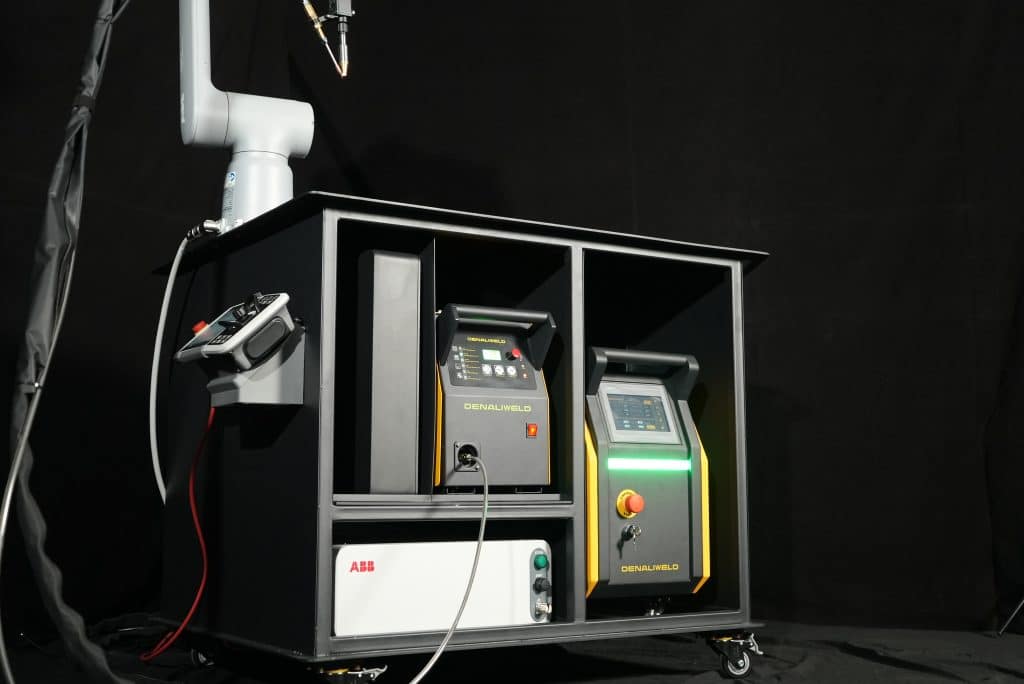

Automation and integration capabilities

As technology continues to evolve, more and more laser welding machines are equipped with automation and integration capabilities, such as CNC controls, robotic arms or customized software interfaces. These characteristics enhance efficiency, precision, and consistency; they are especially well-suited for intricate welding applications and large-scale manufacturing.

However, the realization of these automation and integration features usually requires higher technology and R&D costs, which leads to higher equipment prices. For applications that require efficient production and high quality welding, such as medical device manufacturing and automotive manufacturing, these features may be necessary. For simple welding tasks, however, these advanced features may not be required, and therefore can be chosen from among equipment that is more affordable in terms of price.

Market Demand and Competition

In a competitive market environment, in order to attract customers and maintain market share, manufacturers may adopt a price competition strategy by lowering the selling price of their equipment. This may lead to a decrease in the price level across the market. In addition, factors such as market demand, competitive conditions and tax policies in different regions may also affect the price of equipment.

In some regions where demand is strong, the price of equipment may be relatively high as manufacturers can maintain high profit margins. In areas where demand is weak or competition is fierce, equipment prices may be relatively low. Understanding the local market conditions and competition is an important reference for purchasing laser welding machines.

Warranty and after-sales service

Warranty and after-sales service is one of the important factors to be considered when purchasing a laser welding machine. A good warranty and after-sales service can provide additional safety and reliability and ensure the long-term stable operation of the equipment. Different manufacturers offer different warranty periods and service coverage, so you need to carefully compare and choose the warranty program and service content that suits your needs.

Factors to consider when buying a laser welding machine

Before purchasing a laser welding machine, we need to consider various factors thoroughly to ensure that we can purchase a machine that better meets our needs at a lower cost.

Welding efficiency and performance

The first thing we need to do is to determine the performance of the laser welding machine, we need to consider the welding speed, accuracy, stability and other performance indicators. An efficient welding machine can reduce welding time and rework, increase productivity, and thus reduce overall costs. Therefore, we need to select a welding machine with high performance to ensure long-term cost-effectiveness.

Maintenance and operating costs

These include energy consumption, cooling water costs, wear parts replacement, maintenance labor hours, and operator training. Long-term costs such as technical support, spare parts supply and warranty periods also need to be considered. All of these factors need to be taken into account in the assessment to ensure long-term operational sustainability and economy.

Welding Application Requirements

Different welding applications require different performance and functionality of the laser welding machine. We need to evaluate the type of material to be welded, its thickness, weldability, etc. By understanding these requirements, we can select the laser welding machine that best suits the needs of the application while ensuring its cost-effectiveness.

Return on Investment

We need to evaluate the potential impact of the machine on productivity, labor costs, material savings, and quality improvement. By comparing the initial investment with the long-term benefits, we can determine the ROI of a laser welding machine. In addition, we need to consider the impact of depreciation expenses, tax incentives, and other factors on ROI.

Summarize

This article has provided a more comprehensive analysis of the price of laser welding machines. Understanding these factors can help you better understand why the price of different models and sizes of laser welding machines varies greatly. By taking a closer look at these factors, you can better understand the laser welding machine market and make informed buying decisions. Whether you are a distributor or an end user, you should carefully consider these factors when purchasing a laser welding machine.If you need to get a detailed quotation for your laser welding machine, please contact DENALI and we will get back to you soon.