Laser welding is a precision process that uses a high-energy laser beam to fuse metal workpieces. Compared with traditional welding technology, laser welding has unparalleled advantages in many aspects. Now, the laser welding machine has been used in many areas of maturity, greatly improving the production efficiency of enterprises. So what materials can be welded by laser welding machine? Which material can not use laser welding machine for welding? This article will be analyzed in depth.

The basic principle of laser welding

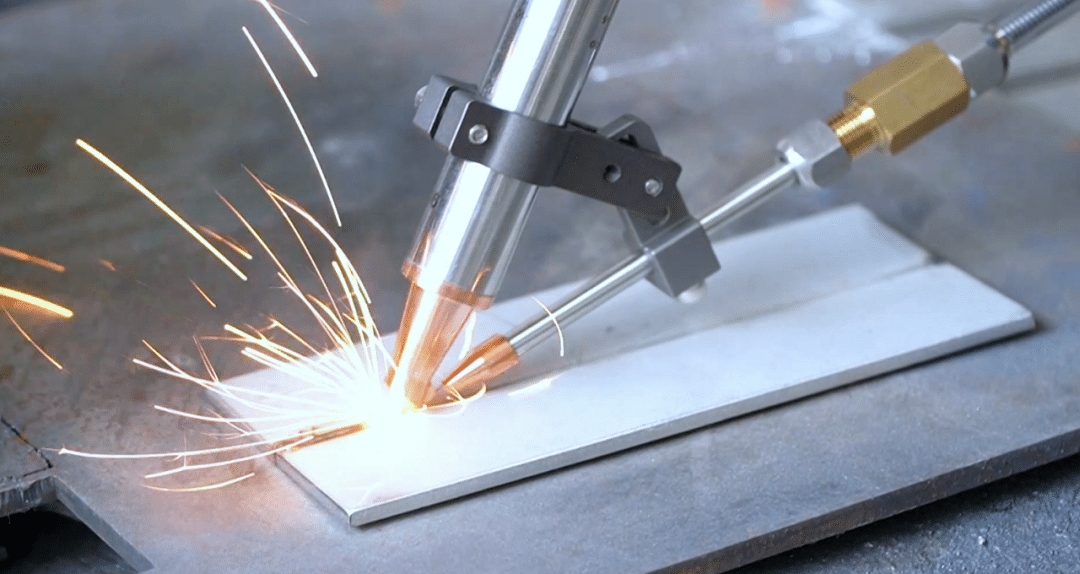

Laser welding is the use of laser generated high-energy laser beam, through the lens and mirrors and other optical components for focusing, irradiation on the surface of the workpiece so that the temperature rises to a high enough temperature, will make the workpiece melting and form and form a molten pool, with the laser beam to move, the molten pool will follow the movement of the laser to stop irradiation of the part of the molten pool will gradually cooled and solidified, so it will be the formation of the next complete weld in the welding path, thereby forming a solid weld. The next complete weld is formed in its welding path, resulting in a solid weld. Compared with traditional welding technology, laser welding is fast, low power consumption, and can realize continuous high-speed welding and improve welding efficiency. Nowadays, laser welding machines have been maturely applied in many fields, widely used in advertising lighting, sanitary ware industry, metal processing, automobile manufacturing, medical equipment, aerospace, electronics manufacturing and many other industries.

Materials that can be welded by laser welding machine

Laser welding machine is known for its wide range of applications, high precision and high efficiency. Compared with traditional welding methods, it has a larger range of applications and can weld a wide variety of metallic and non-metallic materials, principally including the following categories.

Metallic materials

Carbon steel:Better results can be achieved when welding carbon steel using a laser welding machine; the welding quality is determined by the impurity content. When welding steels with different carbon content, the torch can be slightly offset to the side of the low carbon material to ensure the quality of the joint. Weld cracking and notch sensitivity increase as the carbon content increases when welding carbon steel because laser welding machines have extremely quick heating and cooling speeds. Medium to high carbon content steels and common alloy steels can be laser welded well, but require preheating and post-weld treatment to remove stress and minimize cracking.

Stainless steels:Due to the high welding speed and small heat-affected zone of laser welding, the overheating phenomenon and the undesirable effect of large coefficient of linear expansion during welding of stainless steel are mitigated, and the weld is free of defects such as porosity and inclusions. Compared with carbon steel, stainless steel due to a low thermal conductivity, high energy absorption rate and melting efficiency is easier to obtain a deep melt narrow weld. Welding thin plate with low-power laser welding, you can get the appearance of well-formed, smooth and beautiful weld joints.

Titanium and its alloys:Laser welding is gradually expanding its application in the field of industrial welding due to its advantages of environmental protection, low heat impact, and small material deformation, etc. As a titanium alloy applied in some special environments and industries, the advantages of laser welding are even more obvious.

Aluminum and its alloys:The biggest difficulty in laser welding aluminum and aluminum sheet is its high reflectivity to the laser beam. Aluminum is a good conductor of heat and electricity, and its high density of free electrons makes it a good reflector of light, with a starting surface reflectivity of more than 90%, which means that deep melting welds must be initiated at less than 10% of the input energy, which requires a very high input power in order to ensure the necessary power density at the start of the weld.

Other metals include: nickel, tin, copper, chromium and niobium.

Non-metallic materials

Quartz:Laser welding is a commonly used method of joining quartz glass, which enables high-precision welding with the advantages of no contact, no contamination, and a low heat-affected zone. It should be noted that laser welding needs to control the laser power, focal point position, welding speed and other parameters, in order to avoid the quartz glass is subjected to thermal stress and rupture, deformation and so on;

Glass:Laser welding provides a more accurate, efficient and high-quality processing method for glass welding, and it can be envisioned that after the glass welding problem is solved, it will be promising in the field of electronics, engineering, and medicine such as implantable devices and sensors;

Ceramics:Laser welding machine can weld ceramics, but need to pay attention to the brittleness of ceramics and high-temperature stability and other characteristics, to take appropriate operating methods and precautions, in order to achieve high-quality welding;

Plastic:Laser welding plastic dissolution of the whole process less, resulting in less residue, welding operation non-contact, does not cause environmental pollution, laser welding and other interface methods to form the mechanical stress and stress compared to the material is particularly suitable for computer mice, cell phones and soon.

Materials that cannot be welded with a laser welding machine

Not all materials can be welded with a laser, and the following are some of the materials that laser welding is usually unable to weld effectively.

Laser welding requires adequate absorption and heat transfer, while transparent materials have a high transmittance rate, which can make the laser propagate inside the material and prevent welding. For materials such as transparent ceramics, welding can be performed by using localized coating or a secondary heat source to increase material absorption.

Magnesium is an active metal that oxidizes easily and emits gases during welding, resulting in a decrease in weld quality. For the welding of magnesium alloy, argon arc welding, stir friction welding and other methods are required.

Casting aluminum alloy contains a variety of metal elements, easy to produce thermal cracks, porosity and other defects, affecting the welding quality. For the welding of casting aluminum alloy, it is necessary to use implanted tungsten argon arc welding and other methods.

High hardness materials are prone to cracks, deformation and other problems when repairing or welding. For high hardness alloy steel, corundum ceramics and other materials, it is necessary to use laser cladding, laser curing and other methods for connection.

Some materials with high temperature sensitivity, such as thermoplastics, may be affected by overheating in the high-temperature environment of laser welding, resulting in a decline in material properties.

Laser welding requires a relatively dry environment. For highly hygroscopic materials, the welding process may be disturbed by moisture.

Advantages of laser welding

1. Fast welding speed, low power consumption, can realize continuous high-speed welding, improve welding efficiency;

2. It can realize precision welding and beautiful weld seam, which can be applied to high-precision and high-requirement occasions;

3. Simple operation, even non-experts can realize professional welding, without expensive training costs;

4. Small heat-affected zone, small thermal deformation, can reduce the thermal impact on the surrounding materials.

5. High degree of automation of laser welding, with collaborative robots, you can control the welding process through the computer, improve production efficiency;

6. Weldable material types, stainless steel, carbon steel, iron, galvanized sheet, aluminum and its alloys and other materials can be welded;

7. Relatively low maintenance costs, low replacement cost of spare parts, DENALI has a perfect after-sales service, no need to worry about after-sales problems.

What should I be aware of when using a laser welder?

1. Before starting welding must pay attention to safety precautions, the user must wear professional laser protective glasses, protective clothing and gloves and other personal protective equipment, in order to avoid laser damage to the human body.

Welding work, to eliminate any flammable substances present at the scene, set the work area, must be clear that the user and onlookers of the safety distance.

2. Users need to operate in accordance with the operating instructions and related standards, and strictly follow the operating specifications in order to avoid accidents.

3. During the working period, handheld laser welding machine safety norms do not use the eyes to look directly at the laser beam, and do not let any part of the body contact the laser beam, so as not to cause injury.

4. Pay attention to keep the environment and the handheld laser welding machine clean, the use of the process can not be directly on the ground welding head to prevent dust on it.

5. equipment failure, first contact the laser welding machine manufacturers, seek technical help to solve the problem, in the absence of understanding the problem, do not disassemble and repair on their own.

Laser welding machine can make our work efficiency, but in the welding process if the operation is not appropriate, not only affect the welding effect of machinery, but also may damage the machine, in order to ensure the safety of the use of laser welding machine, we must strictly control the laser welding hazards, good personal protection and strengthen safety measures.

Summarize

Laser welding is a technology that can weld materials of different natures and thicknesses. It is suitable for welding a wide range of metallic and non-metallic materials, and is characterized by high efficiency and high precision. The weldability of the material depends on its optical, thermal and chemical properties, and is also affected by the material properties, with certain limitations for some specific materials. With the continuous development of laser technology, it is believed that laser welding will have a wider application in the future.

Learn more about what to look for in a laser welding machine.