Laser welding has become an important process in the welding industry, with the advantages of low thermal distortion and high productivity over conventional welding. In this article, we will look at the factors that affect the efficiency and productivity of the laser welding process and discuss the uses and techniques that can be used to enhance these aspects. By learning this, companies can not only improve weld quality, but also increase production and reduce costs.

Advantages of laser welding machines

Laser welding machine has been maturely applied in many fields, as one of the important components of laser application, laser welding is a combination of modern technology and traditional technology, laser welding machine has some unique advantages over traditional welding equipment.

Fast welding speed, low power consumption, can realize continuous high-speed welding, improve welding efficiency;

Precision welding can be realized, with beautiful weld seam, which can be applied to high-precision and high-demand occasions;

Simple operation, even non-experts can realize professional welding, without expensive training costs;

Small heat-affected zone, small thermal deformation, can reduce the thermal impact on the surrounding materials;

High degree of automation of laser welding, with collaborative robots, you can control the welding process through the computer, improve production efficiency;

Weldable material types, stainless steel, carbon steel, iron, galvanized sheet, aluminum and its alloys and other materials can be welded;

Relatively low maintenance costs, low replacement cost of spare parts, DENALI has a perfect after-sales service, no need to worry about after-sales problems.

Factors affecting the productivity of laser welding machines

As with any manufacturing process, laser welding requires certain techniques of use to improve its efficiency. Understanding the factors that affect the productivity of a laser welding machine is critical to optimizing the performance of your laser welding machine and achieving high quality welds.

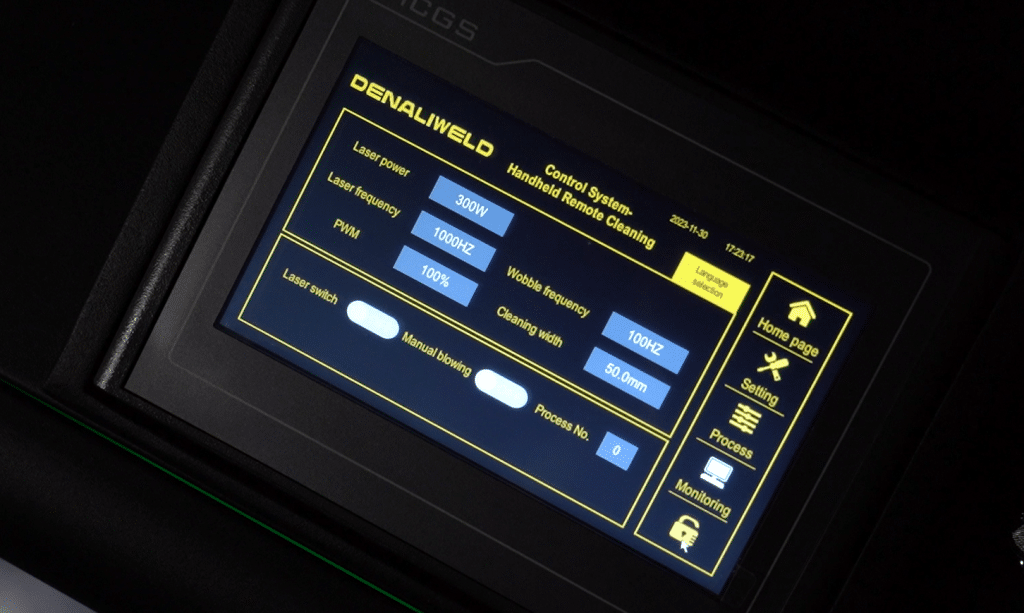

Different machines have different functions and features that can significantly affect the welding process. Machines with advanced control systems and precision optics can ensure accurate and consistent welds, thus improving overall efficiency.

High-power laser welding machines can provide faster welding speeds and deeper depths of fusion. Parameters such as welding speed, focal length and beam diameter can greatly affect the quality and efficiency of the weld. Selecting the optimum parameters is critical to achieving a quality weld and minimizing defects.

Welding efficiency will vary from material to material. Some materials may take longer to weld due to their high reflectivity, which causes the laser energy to be partially reflected.

Inert gas will be used to protect the molten pool during the welding process, but in order to ensure the best welding quality, it is necessary to use a gas with good antioxidant effect, low ionization, and not easy to form a plasma, commonly used gases include argon, nitrogen, helium and so on, and according to the different materials of the weld to choose the appropriate welding auxiliary gas.

Operator skills and experience also affect the efficiency and productivity of laser welding. A trained and skilled operator can effectively operate the machine, monitor the welding process and make the necessary adjustments to optimize weld quality and productivity.

How to increase welding productivity

Select the appropriate welding power according to the characteristics of the material. Generally speaking, high reflective metals such as aluminum alloy need higher welding power than low reflective metals such as carbon steel; the size of the welding power will have a direct impact on the depth of weld, strength, appearance, etc., higher power can achieve faster welding speed and greater depth of weld, but the power of the laser welding is not the higher the better, need to be combined with the material of the workpiece and the thickness of the workpiece as well as the requirements of the welding effect of the choice! Generally speaking, the thicker the plate, the higher the welding power required.

Choosing the wrong type of gas may cause cracks in the weld, resulting in poor strength.

The ionization energy of nitrogen is moderate, and the degree of ionization under the action of laser is average, which can better reduce the formation of plasma cloud, thus increasing the effective utilization of laser. Nitrogen at a certain temperature can be chemical reaction with aluminum alloy, carbon steel, produce nitride, will improve the brittleness of the weld, toughness is reduced, so it is not recommended to use nitrogen on aluminum alloy and carbon steel weld protection. And nitrogen and stainless steel chemical reaction produces nitride can improve the strength of the weld joint, will be conducive to the mechanical properties of the weld to improve, so you can use nitrogen as a protective gas when welding stainless steel.

Argon ionization energy is relatively low, under the action of the laser ionization degree is high, is not conducive to controlling the formation of plasma clouds, will have a certain impact on the effective utilization of laser, but argon activity is very low, it is difficult to chemical reaction with common metals, and argon cost is not high, so it can be used as a conventional protective gas.

Helium ionization energy is high, the ionization degree is very low under the action of the laser, can be very good control of the formation of the plasma cloud, the laser can be very good role in the metal, and helium activity is very low, basically no chemical reaction with the metal, is a very good weld protection gas, but helium cost is too high, the general mass production of type products will not use the gas.

The above three are the most commonly used protective gases, according to the actual situation to choose the type suitable for their use.

The quality of the laser welding machine is also an important factor, poor quality laser welding machine may cause various problems during the use of the machine, which directly affects the production efficiency and the cost of the enterprise.DenaliWeld self-designed laser control system, the output curve is smooth, the welding is smoother, and all of Denali’s laser welding machines have CE, FDA and SGS certificates.

Systematic training for operators before starting work, familiarize with the structure and function of each part of the laser welding machine, understand how to adjust each parameter of the laser welding machine, and ultimately make them skilled in the use of the machine. Training in machine maintenance is also required. The operator’s expertise ensures proper maintenance of the machine, including regular cleaning and calibration, which is essential to maintain the performance of the laser welding machine.

Summary

Laser welding provides precise and efficient welding solutions, and the continued advancement of this technology offers many opportunities for companies to improve efficiency and productivity. The type and quality of the laser welding machine, the selection of appropriate welding parameters, material properties and thickness, and operator skills all have a significant impact on laser welding productivity, and understanding and optimizing these factors can lead to improved weld quality and increased productivity. Manufacturers should pay close attention to this technology and incorporate it into their production processes to achieve higher productivity and greater success.